Great two days at the NECThis is my 'go to' show if I'm available, this year I penned in the Wednesday and Thursday of last week to make sure I could be there for both days.

For me it's a great chance to catch up with friends and collaborators in industry that either have stands there or are attending as well. This year I had arranged to meet a couple of people in person that I've know through LinkedIn for a couple of years. Jamie Borley from Assetivo is an engineer I've talked on the phone to but never met, we had a really interesting hour talking about our own challenges of being independent consultants working with clients. Great to chat with long time collaborators from Senseye who are now part of Siemens since they acquired them a year ago, good to see them now in SIEMENS polo shirts. Footfall this year was very busy on the Wednesday but a lot quieter on the Thursday, it's good to see as the show last year was still trying to get it's mojo back. It had a better location in Hall 4 at the Birmingham NEC which is a lot better than the trek over to Halls 14 & 15. Most stands I talked to were very positive, I can't see the ROI in it for me personally unless I teamed up with another business, it's always good to talk in real life with people and come across synergies where you might be able to help someone out... after all that's what being in business is all about, helping people 🙏

0 Comments

Great to be back onsite in 2023It's great to be back onsite regularly with old colleagues and new connections at Walkers Snack Foods.

Kind of like being back 'home' as I spent over 20 years working at the Coventry site (Doritos), this time it's the home of Walkers Snack Foods at Leicester, Crisp central! Great to have a medium term contract where I can see the difference being made. I'm also enjoying the varied work including, Criticality process, Lubrication Strategy, RCAs, and supporting a new Condition Monitoring engineer. Learning from the Industry of Madeira, PortugalWhat do Engineers do on holiday?

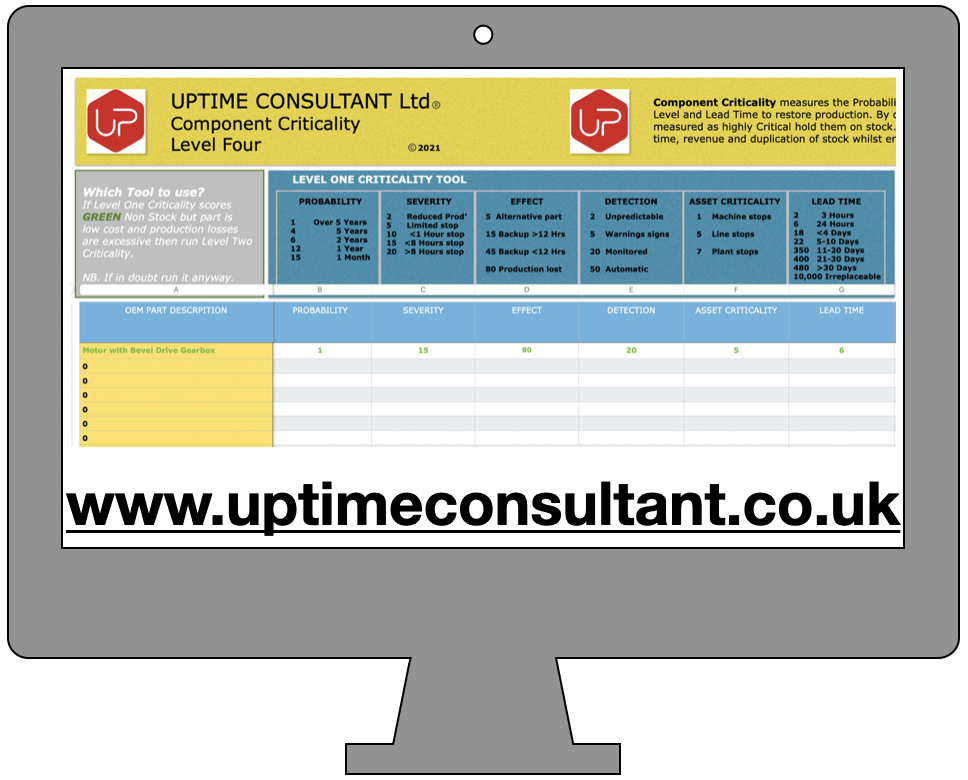

Look for engineering in action, here are just a few snaps of industry on Madeira. I learnt a few things about how the island manufactures buildings, provides power, produces wine, and grows algae! It's always good to learn about how island communities function, they always seem idyllic until you scratch the surface, they have the same problems as mainland communities but with more risks in some places. How we frame your strategy with our Criticality ProcessOne of the tools we've developed over the past few years is a 'Criticality Process' with a twist.

As soon as you mention running a Criticality Study many retort that it's too slow, too costly, and they haven't got the time. This is where UPTIME Consultant can help because our process is (relatively) quick, costs less than you save (all ours have been paid for just with inventory criticality) and we have the time to get it done by concentrating on the task in hand. We have happy customers that will vouch for the above (on request!) we even train them to use the process if they have the inclination. Our process identifies all the assets in a process (new or legacy it doesn't matter), looks at the maintainable components, takes into account OEM recommendations (not always correct), identifies the risk and consequences of failure, accounts for the client's appetite for risk, classifies the spares for stock hold, considers lead times (even more important now), identifies opportunities for proactive/predictive inspections, records Lubrication specifications, recommends maintenance instructions and tasks, highlights skills gaps, and many more aspects. This frames the business Maintenance Strategy for capital equipment, reduces the risk of failure, stocks critical items, increases visibility of aspects that were unknown at the outset. If you want to find out more please get in touch. Always Good to have Positive Feedback!This was from a client who knew they had to find a different way of working... it was the clarity of a third party view that we provided that made the impact.

There have been many challenges coming out of the past two years, especially in manufacturing where disruption to supply chains, staff shortages, and increased costs have made operations think about change. This company had lots of issues covering all of these aspects and more. It only took a day visit and another day to report, within the week they had a whole range of information to act upon, with a Top 10 to do list including the first three to work towards in the next six months. I was also able to introduce some Condition Monitoring aspects and recommend a short list of CMMS applications that would suit their needs as a smaller operation, they actioned one of those recommendations straight away. NEC Birmingham 5-7th April 2022Around two and a half years since I last attended a trade show, back over to the NEC which is only a 10 minute train ride away... although the trains were in a mess returning on the last day due to a broken rail track!

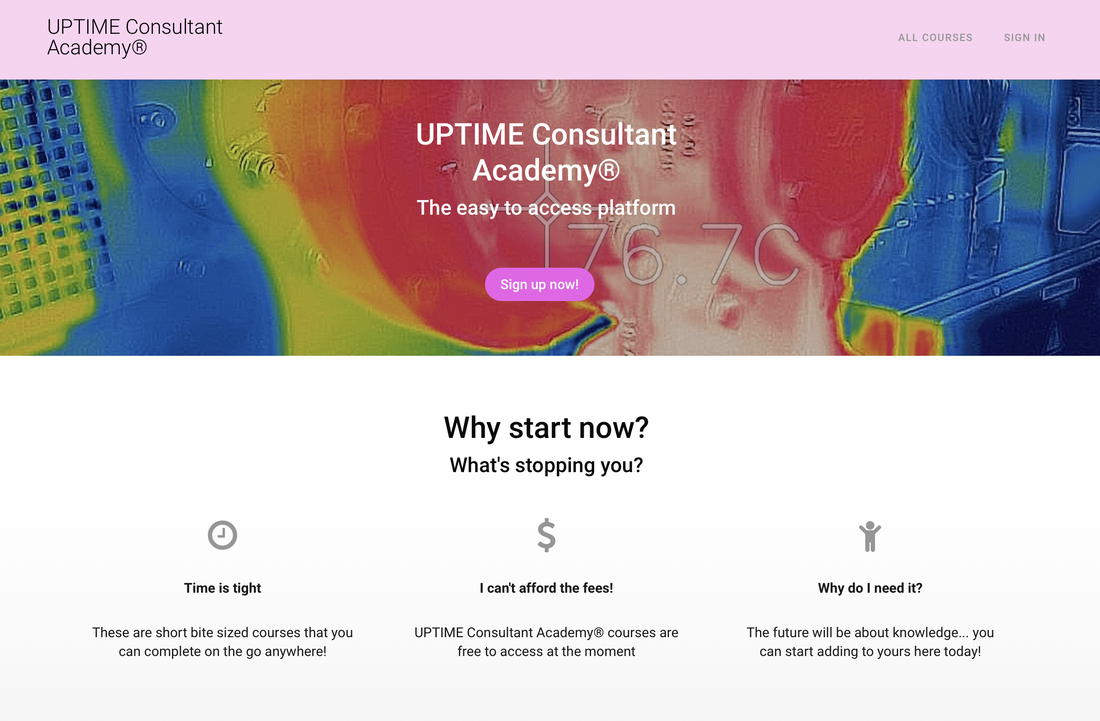

Great to catch up with friends from Senseye, MaintMaster and Pragmatic along with many others. Had some excellent conversations about all things maintenance and reliability, new approaches to business, new sensor systems introduced, and lots of old standards that actually work. Back there in a couple of months for Maintec 2022, say hello if you see the UPTIME Consultant logo👍 New Online Courses for 2022... Five Published in January and more to follow! We have had the UPTIME Consultant Academy® in beta testing for over a year now.

In the background I have been authoring a series of six short courses aimed at the complete novice, but filled with examples from my experience thrown in for good measure! Planning on having more than ten available by the end of Q1 and they are all FREE to access at the moment, so why not sign up and enhance your engineering and maintenance knowledge? UPTIME Consultant's 2021Well what a different year 2021 was... mainly virtual although, I did still spend over twenty days on site visits with clients in the Food and Beverage industry, food production never stops even for a global pandemic!

We did lose a lot of business though in the Automotive and other sectors, hopefully they will return stronger in 2022. by UpKeepAnother TMC by UpKeep webinar, I've become one of TMCs 'Community Champions' which means I've committed to posting a couple of blogs and run two webinars over the next year.

This is the first of those webinars looking at the importance of front line engagement with some tips and insights into what I have found works for me, you have to join TMC now to access these and other webinars. by UpKeepThis was an interesting talk, first I presented a brief story of how a few years ago I looked into thread seizure and ended up referencing a paper from NASA!

It's a good place to look as they have lots of studies about fastenings and failures that are open source. We had a Q&A session afterwards but I must have explained it too well as there weren't many questions to answer. |

Andy

|

RSS Feed

RSS Feed