Condition Monitoring

Condition Monitoring (CM) can often be used as a stand alone discipline, but works more effectively when incorporated into a Holistic Reliability Strategy. Coaching your staff in aspects of CM will reveal asset issues before they result in major unplanned downtime. It's not unusual to find "big wins" immediately, providing you with an instant return on investment.

Condition Monitoring warns of impending failure, identifies the need for lubrication and continuous improvement

- Learn CM from a practitioner with decades of experience formulating a world class Proactive Strategy

- NOT based on theory and expensive instruments, I do advise on the latest predictive technologies

- Positively impact your asset availability by targeting the critical few first to deliver immediate cost benefits

- Autonomous Maintenance training for your front line operators includes many elements of proactive maintenance

UPTIME Consultant trains the techniques relevant to your assets, start your reliability journey whilst enabling your proactive maintenance strategy

- Condition Monitoring

- Vibration

- Acoustic Emission

- Ultrasound

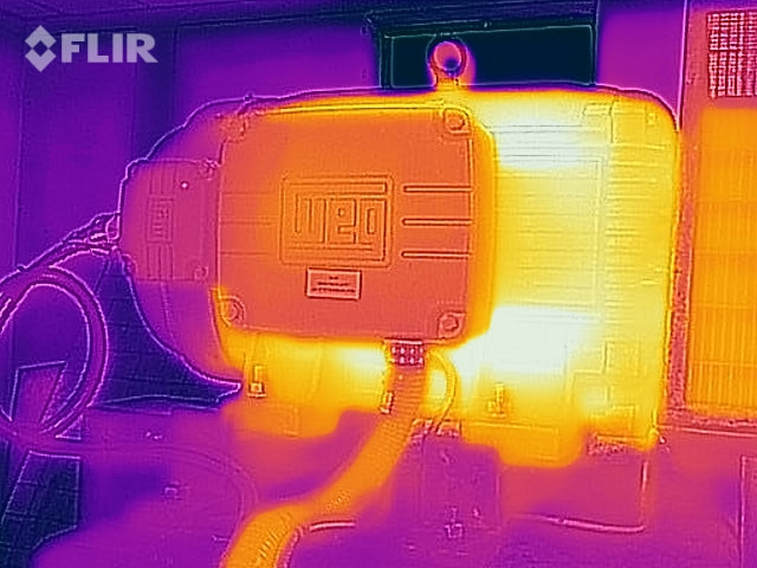

- Thermography

- Oil Sampling/Tribology

- Continuous Monitoring

- Connect Technologies (IIoT)

Your operators and maintainers work closely with your assets everyday, they provide the most effective route to delivering multiple benefits using a well supported Condition Monitoring approach

UPTIME Consultant collaborates with our preferred partners and suppliers of Predictive equipment to suit your requirements

We stay agnostic by never taking percentages or fees from the third parties we introduce to clients if requested

We constantly evaluate developments that can engage front line staff with recent advances in predictive technologies

You can contact me directly: [email protected]

Telephone: 07866 385281

Introducing Condition Monitoring to ENGIE Engineers in the Utility sector

Reliability Driven by Design

Using Predictive Technology to drive design and reliability improvements

Reliability is inherent, it's built in at the design phase, this is where major decisions are made that can impact your asset reliability

We have to accept that the design of all assets and equipment is constrained, by budget, footprint, accessibility, operating context, maintainability, ergonomics, power requirement, health and safety, the list is extensive.

The main thing is the Original Equipment Manufacturer (OEM) has a lot on their plate, conceptualising, specifying and building assets to fit your operating context perfectly, it's little wonder some items may not suit the end user in application.

We assume the OEM understands the end users intention... this is often not the case as we shall see.

Next there is the manufacture and assembly of the asset, what are the standards used to put it together?

Often these expensive assets start as a shopping list of sub assemblies that go towards making up the whole.

Now we have a number of OEMs involved, with different practices and standards all coming together.

These sub systems interact with each other... sometimes not as perfectly as you would expect in service!

When critical assets enter service one of the first things I can guarantee is that it will break down unexpectedly, everyone (except the Proactive/Predictive Engineer) will be shocked!

Early Equipment Failure occurs more often than we would like and is often down to the constraints I mentioned earlier.

The eventual operational context could also be different to the one assumed at the design phase.

The Operations Manager may want this shiny new asset to run above the design envelope immediately, it's more common than you would think, then when it does break down or 'underperform' they ask the maintenance department...

"What are you going to do about it?" or if they are feeling more generous

"Can you make it run more reliable please?"

The main thing is the Original Equipment Manufacturer (OEM) has a lot on their plate, conceptualising, specifying and building assets to fit your operating context perfectly, it's little wonder some items may not suit the end user in application.

We assume the OEM understands the end users intention... this is often not the case as we shall see.

Next there is the manufacture and assembly of the asset, what are the standards used to put it together?

Often these expensive assets start as a shopping list of sub assemblies that go towards making up the whole.

Now we have a number of OEMs involved, with different practices and standards all coming together.

These sub systems interact with each other... sometimes not as perfectly as you would expect in service!

When critical assets enter service one of the first things I can guarantee is that it will break down unexpectedly, everyone (except the Proactive/Predictive Engineer) will be shocked!

Early Equipment Failure occurs more often than we would like and is often down to the constraints I mentioned earlier.

The eventual operational context could also be different to the one assumed at the design phase.

The Operations Manager may want this shiny new asset to run above the design envelope immediately, it's more common than you would think, then when it does break down or 'underperform' they ask the maintenance department...

"What are you going to do about it?" or if they are feeling more generous

"Can you make it run more reliable please?"

Maintenance cannot make assets more reliable than the inherent design, maintenance can only maintain the original design specification... only by redesign can change be achieved

My reliability journey started in 2006, I transitioned from being employed on wasteful reactive and planned maintenance tasks to specialising in Proactive Predictive Techniques and Lubrication.

I was challenged by the then Maintenance Manager to build an integrated Predictive and Lubrication Strategy in Europe's largest snack food plant, part of PepsiCo International.

I was fortunate that the Engineering, Operations and Maintenance Managers allowed me time to investigate and implement what I considered to be the best solutions, then continuously improve, moving from a site heavily weighed down by planned and reactive work to a proactive and predictive one.

But we weren't finished like some, I have seen this in practice with other organisations, they are proud of their extensive Predictive programs. They catch some future failures (saving the day) thereby unwittingly becoming the new 'firefighters' moving from a fully reactive mode to a reactive predictive one!

We targeted the realm of Innovation, eradicating repeated failures, bringing to the surface the hidden niggles that add up to big numbers in lost opportunities was the goal, these non recorded events are usually hidden out of sight but cause major damage.

The best Predictive programs will over time make itself redundant... it becomes that good.

This can only be achieved by eliminating every single weakness identified in your assets, then go do it again, and again.

Early days of my journey in Prediction were punctuated with negative comments and disparaging remarks from colleagues.

I always empathised but never saw it the same, I was never a real Maintenance Engineer as my roots are in Production Engineering.

These guys were proud of saving the operation from another catastrophic failure (with collateral damage lying all around) they enjoyed it because they received plaudits from management and peers, something I always found to be very bizarre!

One excellent reactive maintenance engineer took issue early on with my approach and we had a discussion, I believed Predictive techniques would work if embraced, he thought it was a waste of mine and his time... that we had too many things to fix!

We disagreed amicably with me informing him that my aim was to put him and his colleagues out of reactive maintenance work within a year.

It took a little longer than that, but in this case I later found an advocate for CM, he came to me on several occasions to ask me to inspect motors, gearboxes or bearings he suspected.

I suggested we could do better than that and trained him to use the condition monitoring equipment. My work was done.

The scenario I'm going to share was a critical asset that ran on many other production platforms and came under the most extreme operating conditions of all, these are hot oil fryers. When you examine a Fryer there's not a great deal to go wrong, but when they do it causes multiple waste streams, the complete production line stops, recalls of product occur, waste is produced on shutdown and startup, it generates major losses in labour, power and utility utilisation, it can also involve risky reactive maintenance, the list of multiple losses impacts many KPIs.

None of this is good news, then you still have to make the tonnage you missed, once that time is lost though you never get it back, it's time lost forever!

The elements that can be prone to failure are the main oil pump, pump motor, internal transport belts, control system, heat exchanger, fines removal, in/out feed conveyors, from a Predictive point of view aspects that could not be inspected in operation were the internal belt assemblies, especially the bearings.

These bearings were renewed routinely at planned maintenance intervals but still failed unexpectedly in service, people weren't searching for any solutions though, at best it was a planned activity or reactive work, and at worst major collateral damage, shafts ran in bearing journals, cages disintegrated, ball bearings found in sumps, it was what I refer to as 'custom and practice' the practice of failure had been 'normalised', whilst everyone else talked about the latest grease or different bearing seals I asked the question:

These bearings were renewed routinely at planned maintenance intervals but still failed unexpectedly in service, people weren't searching for any solutions though, at best it was a planned activity or reactive work, and at worst major collateral damage, shafts ran in bearing journals, cages disintegrated, ball bearings found in sumps, it was what I refer to as 'custom and practice' the practice of failure had been 'normalised', whilst everyone else talked about the latest grease or different bearing seals I asked the question:

"Is this assembly fit for purpose or was there a constraint at the design phase that operations and maintenance were now paying the price for in operation?"

Fryers fry product with different types of oil at varying temperatures, these operate around 180ºC (356ºF), pumped through the fryer bed to create a directional wash, some bearings sit out of the cooking oil with others are immersed.

If the lubricant is up to it (and H1 Food Safe) and manages to keep the cooking oil out you may just about get away with it.

H1 Food Safe Greases that operate at this temperature are rare and very expensive to purchase.

Periodically the whole fryer and system is boiled out with a procedure involving caustic agents, this gets into everything including these critical bearings. I considered the predictive strategy I used to be a tool for driving improvements, not a discrete function in itself, this is where some get it wrong, Predictive activity should be there to make a difference, eradicating reactive work completely.

I trawled the internet and found a company that provided the eventual solution to the extreme operating context, a bearing that doesn't require grease, designed for use in hot oil fryers.

The Engineering Manager could see the obvious benefits even when I explained the additional cost of retro fitting a complete set, but I did make the decision easier by presenting the historical failures recorded in the Maintenance Management System along with the projected savings by removing expensive lubrication PMs, removing unplanned downtime and the invaluable price of confidence, knowing that these assets would be available to operations with increased reliability.

If the lubricant is up to it (and H1 Food Safe) and manages to keep the cooking oil out you may just about get away with it.

H1 Food Safe Greases that operate at this temperature are rare and very expensive to purchase.

Periodically the whole fryer and system is boiled out with a procedure involving caustic agents, this gets into everything including these critical bearings. I considered the predictive strategy I used to be a tool for driving improvements, not a discrete function in itself, this is where some get it wrong, Predictive activity should be there to make a difference, eradicating reactive work completely.

I trawled the internet and found a company that provided the eventual solution to the extreme operating context, a bearing that doesn't require grease, designed for use in hot oil fryers.

The Engineering Manager could see the obvious benefits even when I explained the additional cost of retro fitting a complete set, but I did make the decision easier by presenting the historical failures recorded in the Maintenance Management System along with the projected savings by removing expensive lubrication PMs, removing unplanned downtime and the invaluable price of confidence, knowing that these assets would be available to operations with increased reliability.

A full bearing set change was carried out in a planned maintenance window and shared with the maintainers.

I asked them not to intervene but report any anomalies they found in the modified PM inspection routine, zero failures were identified in the 18 months of the guarantee period the bearing manufacturer recommended, we pushed the first change to 22 months mainly because of operational demand.

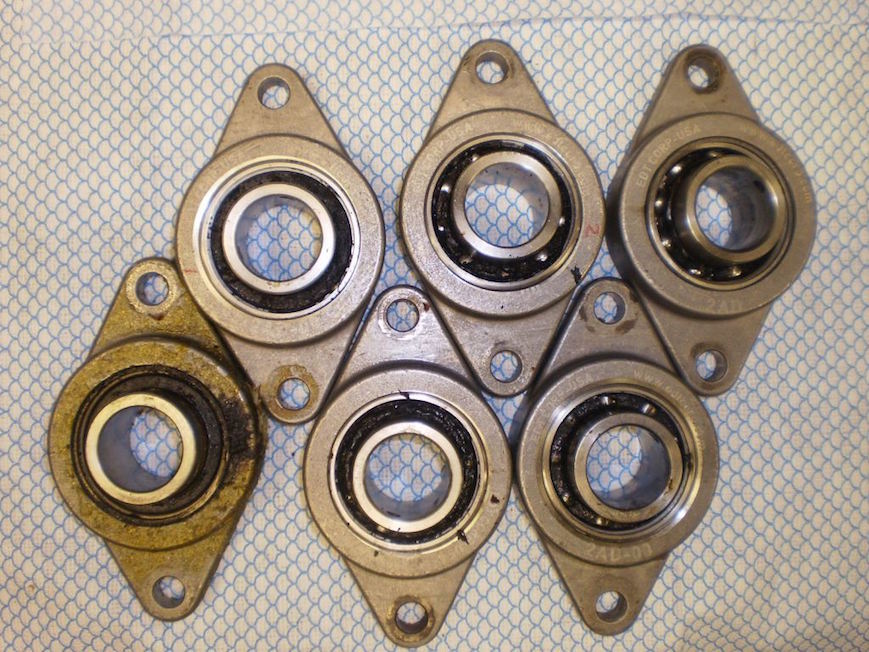

The original set was removed and I retained them for further inspection, a full new set was fitted, later I removed the metal shields from the used set and found them to be in excellent condition. See below:

I asked them not to intervene but report any anomalies they found in the modified PM inspection routine, zero failures were identified in the 18 months of the guarantee period the bearing manufacturer recommended, we pushed the first change to 22 months mainly because of operational demand.

The original set was removed and I retained them for further inspection, a full new set was fitted, later I removed the metal shields from the used set and found them to be in excellent condition. See below:

I followed this up as a side project to my usual Predictive work and managed the retrofits on four additional fryers in the plant over the following three years, remember that reliability is a journey, it can only be improved by design change... it's more a marathon than a sprint!

This story came full circle when a new production line and fryer were commissioned.

I seized the opportunity to get reliability built-in at the design phase, it took a lot of work to make this happen, the product specialist, engineering and projects team had to agree this was the right thing to do.

There was a lot of push back from the OEMs and project team, they believed they owed nothing to operations, maintenance or in-service reliability, they imagined that they just delivered equipment, this type of request was new to them.

Eventually they agreed to provide installed bearings fit for service, the new fryer was assembled with polymer filled bearings now specified as an OEM part.

This story came full circle when a new production line and fryer were commissioned.

I seized the opportunity to get reliability built-in at the design phase, it took a lot of work to make this happen, the product specialist, engineering and projects team had to agree this was the right thing to do.

There was a lot of push back from the OEMs and project team, they believed they owed nothing to operations, maintenance or in-service reliability, they imagined that they just delivered equipment, this type of request was new to them.

Eventually they agreed to provide installed bearings fit for service, the new fryer was assembled with polymer filled bearings now specified as an OEM part.

If this sounds easy it's not... and if anybody tells you it is, they are lying

This is hard, you have to be persistent, have constancy of purpose, form allies, leverage goodwill, prove the benefits (at least twice!) and be confident enough to challenge other people's assumptions.

Arm yourself with hard evidence and facts, thousands of £, $ or € in cost avoidance usually concentrates minds!

Hope this is a worthwhile example, don't let your predictive practices lapse into one that becomes reactive prediction.

Remember the aim of the game is to eliminate failures, not to be relegated to a tool for more reaction!

A big shout out to EDT Corp an innovative company that The Timken Company liked so much they bought them.

If you would like to specify any of their products for your assets here in the UK I can help out with my EDT product knowledge.

If you would like to employ some of these and other Reliability Strategies then you can email me direct at: [email protected]

Arm yourself with hard evidence and facts, thousands of £, $ or € in cost avoidance usually concentrates minds!

Hope this is a worthwhile example, don't let your predictive practices lapse into one that becomes reactive prediction.

Remember the aim of the game is to eliminate failures, not to be relegated to a tool for more reaction!

A big shout out to EDT Corp an innovative company that The Timken Company liked so much they bought them.

If you would like to specify any of their products for your assets here in the UK I can help out with my EDT product knowledge.

If you would like to employ some of these and other Reliability Strategies then you can email me direct at: [email protected]

Criticality of Spares in Proactive Maintenance

Making sure your Proactive strategy supports procurement and spares availability is crucial

Talking to a client about introducing proactive/predictive practices with training to identify the techniques that suited their assets he asked the question:

"Why should we do predictive in the first place, and how do we make all that extra work pay back?"

One thing I pointed out was ensuring confidence in your spares inventory... he reacted like I threw him a curve ball!

I'm a great believer that Proactive and Predictive techniques can't exist in a bubble, to get the best results there are many other pieces that have to fit in place, this is a puzzle that some struggle with.

Logically, if I am going to invest in training people in Condition Based Maintenance, Predictive technology, and being Proactive then when these techniques do deliver we must make sure that inventory control is also proactive, not trapped in a reactive cycle.

This is where some Predictive plans fail, if the correct spare is not available to put that future reactive event into a planned controlled one then credibility will be lost and fingers will point towards the Proactive program not being effective.

Engineering should be the owners of the spares stock and oversee the procurement.

I say oversee because purchasing has a role to procure the correct specification of spare in the correct location in a timely way.

Maintenance should be close to procurement, making sure that the specification and quality of the required parts is fit for purpose.

I could have two identical bearings sat in front of me that look the same, smell the same but one is specified for it's operating context whereas the other can often be sub standard and be prone to early failure.

Purchasing may not understand the nuances of parts selection... it's not always cost effective to buy cheap.

Logically, if I am going to invest in training people in Condition Based Maintenance, Predictive technology, and being Proactive then when these techniques do deliver we must make sure that inventory control is also proactive, not trapped in a reactive cycle.

This is where some Predictive plans fail, if the correct spare is not available to put that future reactive event into a planned controlled one then credibility will be lost and fingers will point towards the Proactive program not being effective.

Engineering should be the owners of the spares stock and oversee the procurement.

I say oversee because purchasing has a role to procure the correct specification of spare in the correct location in a timely way.

Maintenance should be close to procurement, making sure that the specification and quality of the required parts is fit for purpose.

I could have two identical bearings sat in front of me that look the same, smell the same but one is specified for it's operating context whereas the other can often be sub standard and be prone to early failure.

Purchasing may not understand the nuances of parts selection... it's not always cost effective to buy cheap.

You may need to justify the specification of your part to procurement, and you should as their job includes budget responsibilities

You can have the finest on-line remote, internet of things, AI, labour intensive, trained predictive maintenance program, but without those critical spare parts available it will add no value.

Be mindful of the importance of keeping stores people informed, help them by highlighting stock location anomalies, low levels of critical spares, indicate if you are booking the last or penultimate part out, it all makes good sense to help each other out.

Stores personnel hold a lot of information about parts on computerised systems and in their heads, but they can't be expected to understand all the environmental conditions these items have to fulfil in service.

Be mindful of the importance of keeping stores people informed, help them by highlighting stock location anomalies, low levels of critical spares, indicate if you are booking the last or penultimate part out, it all makes good sense to help each other out.

Stores personnel hold a lot of information about parts on computerised systems and in their heads, but they can't be expected to understand all the environmental conditions these items have to fulfil in service.

Remember the consequences are multiple if you get caught out in this situation, the asset may not have entered a reactive phase (yet!) but now the procurement department goes into a reactive spasm of searching databases to see if the parts are on hand in another location, hoping their stockist has the part (or a similar one 'that will do' = future breakdown) or paying a premium for overnight shipping by courier.

Criticality of assets, lead time for spares, stock levels, specialist applications, high turnovers, rebuild times, shipping locations, all of these impact spares availability, we have to preempt all these to make sure we have the right spare at the right time and in the right place.

If you are fortunate and have this all covered so that the right spare, time and place is a done deal don't just leave it there.

Spares need to be looked after, some even require maintenance themselves.

Ensure that the best conditions possible are available, storage of spares in damp, dusty or vibration intense locations will be detrimental and will lead to premature failure when they are eventually put into service.

Large rotary items should be maintained periodically by rotating their shafts.

I would always opt for 'dry' units that are replenished when put into service, it's no use having a gearbox sitting for years full of degrading oil. Vibration of floors or storage racks can damage bearing races in equipment through false brinelling, this causes bearing races to form damaging ridges due to fretting leading to early failure when in operation.

Some other things to watch out for are bearings, seals and other parts removed from protective packaging and stored in open boxes, no system of stock rotation, open access to stores, prevalence of 'emergency orders', lack of inventory control i.e. no booking out system or one that is too hard to use, obsolete parts and duplication (I've previously seen one bearing with eight different part numbers!)

These are just a few aspects that spring to mind, I'm sure you can think of more.

In conclusion, inventory and procurement is a critical function if you aim to get the best from your Proactive Predictive program.

It's all part of a holistic engineering maintenance approach that I am keen on sharing at UPTIME Consultant.

Criticality of assets, lead time for spares, stock levels, specialist applications, high turnovers, rebuild times, shipping locations, all of these impact spares availability, we have to preempt all these to make sure we have the right spare at the right time and in the right place.

If you are fortunate and have this all covered so that the right spare, time and place is a done deal don't just leave it there.

Spares need to be looked after, some even require maintenance themselves.

Ensure that the best conditions possible are available, storage of spares in damp, dusty or vibration intense locations will be detrimental and will lead to premature failure when they are eventually put into service.

Large rotary items should be maintained periodically by rotating their shafts.

I would always opt for 'dry' units that are replenished when put into service, it's no use having a gearbox sitting for years full of degrading oil. Vibration of floors or storage racks can damage bearing races in equipment through false brinelling, this causes bearing races to form damaging ridges due to fretting leading to early failure when in operation.

Some other things to watch out for are bearings, seals and other parts removed from protective packaging and stored in open boxes, no system of stock rotation, open access to stores, prevalence of 'emergency orders', lack of inventory control i.e. no booking out system or one that is too hard to use, obsolete parts and duplication (I've previously seen one bearing with eight different part numbers!)

These are just a few aspects that spring to mind, I'm sure you can think of more.

In conclusion, inventory and procurement is a critical function if you aim to get the best from your Proactive Predictive program.

It's all part of a holistic engineering maintenance approach that I am keen on sharing at UPTIME Consultant.

If you would like to know more, require advice, training or a helping hand then please get in touch with me at [email protected]

Predictive Techniques with Front Line Engagement

Ensuring payback from your Predictive Strategy

As part of my travels through industries I get insights into a wide range of sectors including, Food, Automotive, Utilities, Waste Recycling and FMCG.

Requests are usually for an introducing to predictive methods, with a view to move away from a reactive situation, or move from fixed time planned maintenance.

As a Production Engineer with experience of working not just with machinery but front line staff, it gives me an understanding of how to get the most from deploying Proactive/Predictive techniques as part of a maintenance strategy.

This article is going to be too short to look at the big picture so apologies for not mentioning something you think should be included; remember if you want to cover another aspect then you can write an article of your own.

Something I ask clients to think about before visiting is: Who, What, Why, Where and When, also referred to as my 5Ws.

By asking these questions it gives me information about how far forward they are in their thinking, even if they have actually contemplated these issues.

I also ask "What are the benefits you are targeting?"

If there are no benefits... why bother investing time, money and resources?

It's best to identify benefits before a program is started, this forces you to measure your start point and encourages you to track future progress.

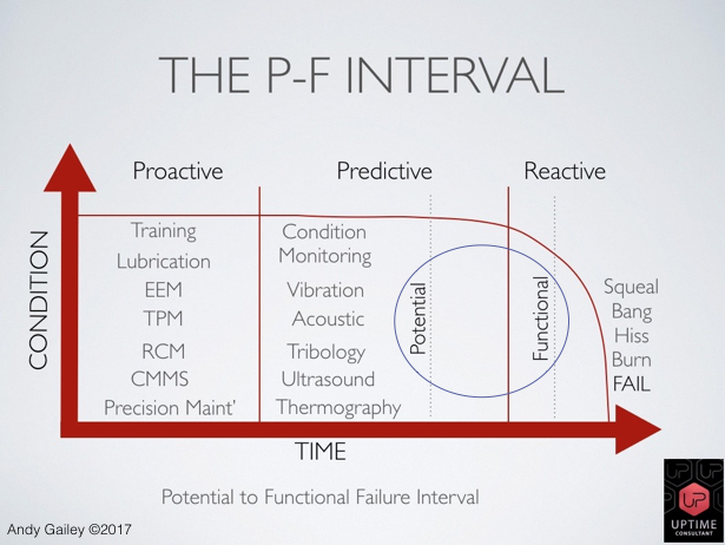

Above... the much used and sometimes misrepresented P-F Interval modified to display more readily what this 'Interval' actually represents.

P = Potential and F = Functional, exists on the timeline of all assets or items as they approach the end of life on the far right, note the FAIL on here is not the 'F' of the P-F Interval... and all assets represent differently in an often chaotic fashion!

Potential for failure is shown as a dotted line, by that I am conveying that it's not fixed, neither is the Functional; functional is when your asset no longer performs at it's designed optimum run rate etc.

RCM II Edition 2 - John Moubray states 'unable to fulfil a function to a standard which is acceptable to the user' slightly modified from the original print that states 'the inability of an asset to meet a desired standard of performance'

The second edition that includes what the user requires was the edit to the definition.

Lots of Reliability papers will set out that all you need to find out is the Mean Time Between Failure (MTBF) and action the asset before that point.. this doesn't add up though because over 80% of all failures are random in nature.

MTBF is a historical measure, sometimes ancient history : /

How many failures do we need to see before we get the latest estimate of 'Mean Time'!!

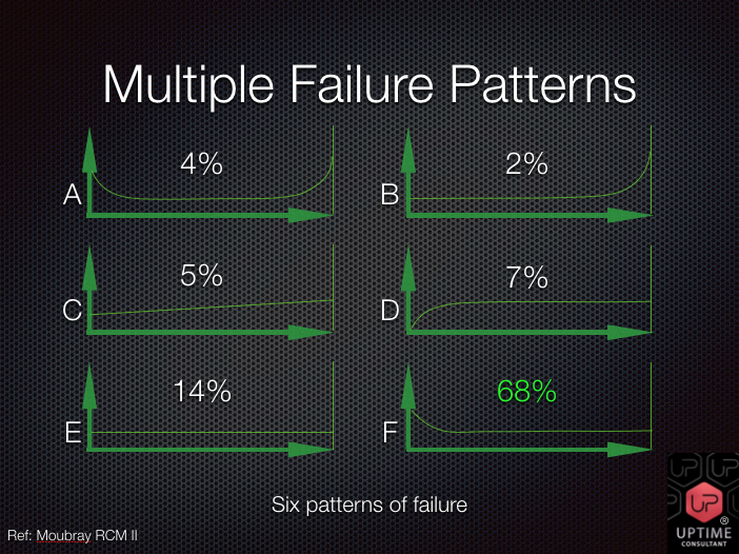

Above I've shown the six known failure patterns identified by Nolan & Heap within the 1978 RCM paper, here applied to other industries outside of aviation by Moubray.

'E' represents the flat line 100% random failure at any point.

'F' shows early mortality again with a random steady state following, both these modes total 82% of the six failure patterns.

Traditional time based wear is represented by the 2% shown in graph 'B'

The often taught 'Bathtub Curve' at 'A' provides only 4% of recorded failures.

A Predictive technique (to provide a benefit) needs to identify the P-F interval as far ahead of time as is required for the asset to be actioned and restored to full health in a future planned event.

This sounds easier than it is in the real world, to start with you have to deploy a predictive strategy closely allied to operational availability, scheduling and planning, without this you run the risk of missing an opportunity to action any found anomalies in a timely fashion, the failure occurs first. The predictive technique applied also has to fit the mode of failure, not all predictive tools are equal, each has their place dependant on how accessible the component is and how it fails.

There are a number of approaches that can be adopted that include; use no predictive, a Predictive contractor visits periodically, full time Proactive/Predictive specialist, a Proactive team, connected Predictive solutions or a Proactive/Predictive enabled workforce.

They all have their pros and cons depending on your appetite for operational risk.

Some have a large appetite and opt for a traditional run to failure strategy, this might be justified by budget constraints or the organisation being happy with the status quo.

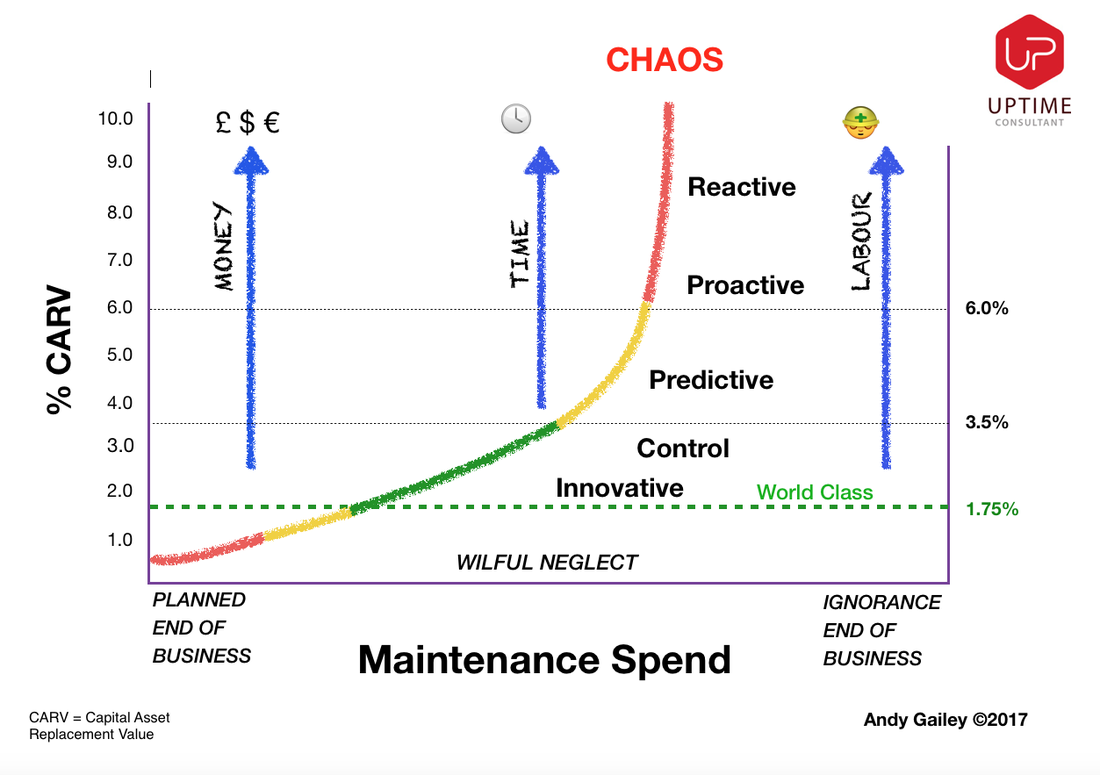

The UPTIME Consultant infographic above I produced to visualise a Maintenance Spend that describes the different levels an organisation may find themselves in.

It's not wrong to be Reactive whilst overspending on parts, labour, time and resource, it's just where some companies decide to operate; they may over time find that this is an unsustainable model.

A Predictive contractor may work on a small number of high value critical assets that are targeted, these periodic inspections can prove to be too long between visits to identify the potential for failure.

The Predictive function in house also has pros and cons, the practitioner requires support with ongoing training and development, it's important that they are released from all other duties and an investment in instruments and technology has to be factored in; remember that ROI needs to be proven to return at least the overall costs of any program.

Predictive teams sound like a good idea but they can suffer from lack of focus, sometimes become an information gathering exercise instead of a benefit that provides a solution.

Prediction as a fully integrated solution is the future, don't believe all the hype about IIoT, it's coming but still will take a big shift in investment practices and thinking before we see it everywhere in the production environment.

'Predictive Techniques with Front Line Engagement' as my title eludes to is the Predictive enabled workforce, this is where real value is added with investment in awareness and training.

It's our people that spend their time operating these assets, they should be empowered to become the owners and ultimately the decision makers regarding their assets, working within the overall mission of the operation.

The future I believe will include the totally connected facility, where machines feedback operating parameters allied with asset health information, integrated into scheduling, maintenance resources and procurement.

Parts of this jigsaw already exist, but at the moment it's like that second hand one you bought at a car boot with three jigsaws mixed together with half the pieces missing!

I believe the untapped resource is the front line operator, training proactive predictive team members is the way forward... until we can identify all those missing pieces!

Condition Monitoring and the impact on Safety, Sustainability and Costs

Saving Time and Money with Condition Monitoring

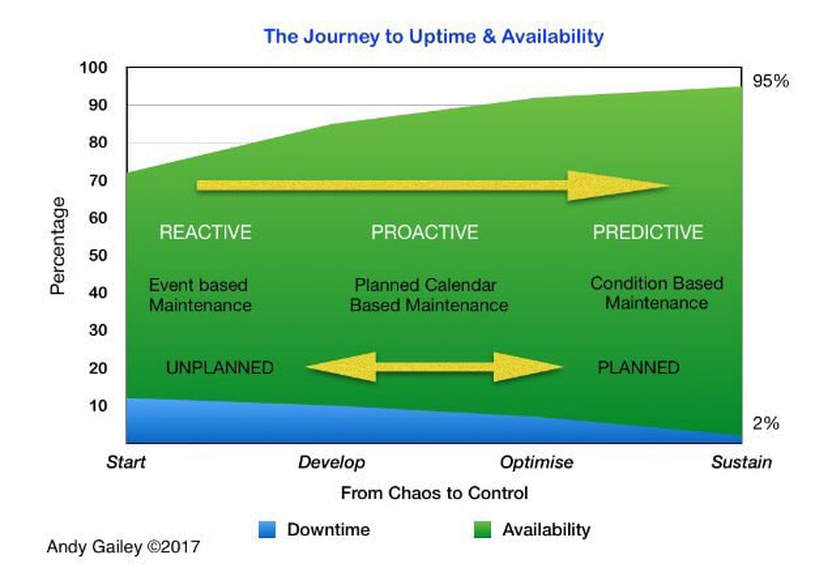

Starting the journey to a Predictive future

Predictive Techniques can get bad press... usually from the Fire Brigade!

Not the ones that save your life when your house is burning down.

These fire fighting heroes are the ones of reactive maintenance, ready like coiled springs awaiting their call to action stations!

Why bother with a Predictive outlook when we have planned maintenance, surely that covers all the eventualities?

At least until the next unplanned breakdown occurs and we call the emergency response team!

I just can't see why people are so anti predictive, after all it is reactive in essence, it's just that we are 'reacting' way ahead of the Functional Failure (F) in the P-F interval and can stop the assets hitting the deck.

Predictive techniques use tools as a planned maintenance activity, we take routine measurements based on criticality, risks, safety and ease of maintenance.

I see it as logic based on facts, things break, we don't know when, we want avoid or mitigate that risk, let's use a technology that enhances our natural senses, we get an early warning, great... now I can plan in a change activity to avoid the consequences.

These fire fighting heroes are the ones of reactive maintenance, ready like coiled springs awaiting their call to action stations!

Why bother with a Predictive outlook when we have planned maintenance, surely that covers all the eventualities?

At least until the next unplanned breakdown occurs and we call the emergency response team!

I just can't see why people are so anti predictive, after all it is reactive in essence, it's just that we are 'reacting' way ahead of the Functional Failure (F) in the P-F interval and can stop the assets hitting the deck.

Predictive techniques use tools as a planned maintenance activity, we take routine measurements based on criticality, risks, safety and ease of maintenance.

I see it as logic based on facts, things break, we don't know when, we want avoid or mitigate that risk, let's use a technology that enhances our natural senses, we get an early warning, great... now I can plan in a change activity to avoid the consequences.

I always say if your business experiences consequences due to unplanned stoppages then you need to invest in becoming proactive and predictive

Most operations sit somewhere on the time line of my 'Chaos to Control' infographic, some accept where they are, whilst others may want to move towards the right hand side.

To be on the left is not wrong per se, it's just where you may find yourself today.

It will feel uncomfortable, disjointed, stressful, haphazard, hard to plan, but the fire fighters will love working there, heroes of the day and rewarded accordingly.

Some organisations will be in the middle with lots of comfortable PMs that are managed and scheduled on a repeated cycle, some may get missed but those can go on backlog, on and on they will go for ever adding no value, but at least it feels safe.

The fire fighters still get their days out with back slaps and hi fives all around

Far right, hold on what's happening here?!?

We are operating in a planned way, operations are happy (who ever heard of that) availability is no longer a bottleneck, the PMs have been put to sleep, criticality has highlighted major issues, RCA is adopted where triggered, front line operators partnered with maintenance, predictive technologies are being used where risks or ROI have been identified, assets are now maintained only 'On Condition', there's less stress and now there is time for Continuous Improvement activity to take place.

Sounds too easy right?

That's true, no one gets a free ride to World Class Reliability, the start begins with a vision from a high level in an organisation to take the journey to this future state.

Some talk of a changing the culture on the shop floor, incorrect, it takes a cultural shift across the whole organisation, it can't be administered in a silo.

Then there's the word 'culture' that means different things to different people, we need to be clear and describe what we are really looking for.

I'm going for this definition: 'the attitude and behavioural characteristic of a particular social group' some will instantly say that the 'attitude' needs changing, well I say good luck with that one.

For me 'behaviour' equals 'habits' and people learn and adopt bad habits as well as good ones.

This could take up a whole new post so I will leave it there for now.

What do you think?

Can you really change peoples attitude?

I believe attitudes change only when new habits and behaviours are adopted, that for me is the key.

"Our people are our most valuable asset"

This is a mantra that's often rolled out... but often lacking in reality.

With process driven industries, people and what they do day to day (habits) present the best opportunity to get ahead when introducing a proactive predictive mindset.

People closest to the assets that drive the bottom line are vastly undervalued in my opinion and can be a largely wasted resource.

When I visit a new process or operation the operators are the people I want to talk to, often they are hungry to be asked 'What do you think?' the conversation with me as a third party allows them to tell it how it is, usually because no one else has bothered to ask them!

They provide invaluable insights that can provide real benefits very quickly.

These are the people that Proactive and Predictive training should be aimed at, they are 'present' they 'operate' their assets every day, by changes in habit maybe we can allow them to 'care' for their assets, provide ownership, then they can influence the change to a more predictive and proactive future.

My friends and Engineers from NISSAN Motor Manufacturing UK enjoying their UCL Introduction to Predictive Techniques

The Fire Fighters are an ageing cohort they are not being replaced, one day when the process hits the floor there will be no emergency response team

I started this article like all of them with a thought and a blank screen.

My first option was to go down the path of the predictive technologies, how they can be introduced, the ROI conversation, importance of criticality, safety, risks, all the usual stuff.

Quickly I realised I wanted to talk about where the real Proactive Predictive journey starts, with front line employees adding value day in day out.

Some businesses will have already started their journey, they will have set backs, hiccups along the way, smart ones know this is all part of a bigger picture, some give up and regress to the 'comfortable' status quo of old reactive habits.

If you would like to talk about your plans reach out at: [email protected]

Telephone direct: 07866 385281

My first option was to go down the path of the predictive technologies, how they can be introduced, the ROI conversation, importance of criticality, safety, risks, all the usual stuff.

Quickly I realised I wanted to talk about where the real Proactive Predictive journey starts, with front line employees adding value day in day out.

Some businesses will have already started their journey, they will have set backs, hiccups along the way, smart ones know this is all part of a bigger picture, some give up and regress to the 'comfortable' status quo of old reactive habits.

If you would like to talk about your plans reach out at: [email protected]

Telephone direct: 07866 385281