Lubrication and Tribology

Lubrication is undervalued, ignore it and you risk the reliability of all your mechanical assets

Most people know what is meant by Lubrication... but some may not understand Tribology.

Lubrication is the process of introducing a substance to keep moving parts apart.

Tribology is the science of moving surfaces interacting with each other, this includes the design and specification of bearings, study of friction, wear, and lubrication.

UPTIME Consultant has a holistic approach to maintenance and reliability, we consider not only how to lubricate an asset, but think about the bearing specification, lubrication standard, training, how components fail in service, total lifespan, detecting potential failure with predictive tools, all these fit together in our holistic strategy.

We have experience of formulating Lubrication Strategies linked with Predictive Technologies to manage lubrication by condition, removing wasteful time based tasks and reducing the reliance on planned maintenance activities.

We help with specifications of grease, oil or bearing type to drive efficiency savings as well as increasing uptime availability.

I have trained with Rocol and Interflon as a Lubrication Trainer for Maintainers and Operators.

More information about how to form a Lubrication Strategy is available in the UPTIME Consultant articles shared below.

If you would like a work proposal or chat about your Lubrication Strategy then please contact me at: [email protected]

We also have a free short Lubrication course on our UPTIME Consultant Academy®

Lubrication is the process of introducing a substance to keep moving parts apart.

Tribology is the science of moving surfaces interacting with each other, this includes the design and specification of bearings, study of friction, wear, and lubrication.

UPTIME Consultant has a holistic approach to maintenance and reliability, we consider not only how to lubricate an asset, but think about the bearing specification, lubrication standard, training, how components fail in service, total lifespan, detecting potential failure with predictive tools, all these fit together in our holistic strategy.

We have experience of formulating Lubrication Strategies linked with Predictive Technologies to manage lubrication by condition, removing wasteful time based tasks and reducing the reliance on planned maintenance activities.

We help with specifications of grease, oil or bearing type to drive efficiency savings as well as increasing uptime availability.

I have trained with Rocol and Interflon as a Lubrication Trainer for Maintainers and Operators.

More information about how to form a Lubrication Strategy is available in the UPTIME Consultant articles shared below.

If you would like a work proposal or chat about your Lubrication Strategy then please contact me at: [email protected]

We also have a free short Lubrication course on our UPTIME Consultant Academy®

Lubrication Articles

Oil Sampling

Oil Sampling, here I share some tips about how, when and where to sample along with the all important return on investment

The importance of having a Lubrication Strategy can't be understated, unfortunately this is disregarded in some parts of industry.

Previously I've talked about how Predictive Maintenance fits in with a Lubrication strategy.

The part that links both is the Oil Sample, it's a proactive tool that provides the earliest advanced warnings of internal equipment issues, it tracks oil quality and provides information to manage oil replenishment or other improvement activity.

Of all the proactive tools this is the one that some say is the easiest to pick up and implement, but it's also easy to take samples that provide little or no value that give incorrect information.

Like all the techniques a level of knowledge and training is required before you can capture meaningful samples.

One of the simplest forms of monitoring is the sight glass.

I'm assuming you can see through your level sight glass?

The first failure is a fogged glass that gives little or no visibility, invest in a new one.

You also need to know what to look for, you can't ascertain the lubricant quality with this subjective method.

If you are going to give yourself a chance at least fit a new sight glass and a sampling port in the correct location.

Previously I've talked about how Predictive Maintenance fits in with a Lubrication strategy.

The part that links both is the Oil Sample, it's a proactive tool that provides the earliest advanced warnings of internal equipment issues, it tracks oil quality and provides information to manage oil replenishment or other improvement activity.

Of all the proactive tools this is the one that some say is the easiest to pick up and implement, but it's also easy to take samples that provide little or no value that give incorrect information.

Like all the techniques a level of knowledge and training is required before you can capture meaningful samples.

One of the simplest forms of monitoring is the sight glass.

I'm assuming you can see through your level sight glass?

The first failure is a fogged glass that gives little or no visibility, invest in a new one.

You also need to know what to look for, you can't ascertain the lubricant quality with this subjective method.

If you are going to give yourself a chance at least fit a new sight glass and a sampling port in the correct location.

First question you should ask about sampling is WHY?

Why am I sampling, for what purpose and will the oil samples at least payback the cost?

What are the benefits, how critical is the asset, does it warrant lubricant monitoring?

Is there a history of failure where the root cause was lubricant related, is the oil change activity expensive, is there a safety risk when carrying oil changes out?

Consider the other associated costs of annual oil changes, is a time based approach really the best we can do?

Why am I sampling, for what purpose and will the oil samples at least payback the cost?

What are the benefits, how critical is the asset, does it warrant lubricant monitoring?

Is there a history of failure where the root cause was lubricant related, is the oil change activity expensive, is there a safety risk when carrying oil changes out?

Consider the other associated costs of annual oil changes, is a time based approach really the best we can do?

Payback comes in many forms, people often say they find it hard to justify ROI, I find it quite easy, it comes down to risk, safety, volume, criticality and cost.

Lubricants are getting more expensive, in the food sector it's not unusual to find smaller volumes that easily cost over £1000 in oil alone; does a timed change provide the best value and use of this finite resource?

Lubricants are also getting smarter with some synthetics lasting 3-5 times longer.

Lubrication requires managing, that's why I always advise sites to have a Lubrication champion who is responsible for tracking use, taking samples and working it partnership with their lubricant supplier.

Lubricants are also getting smarter with some synthetics lasting 3-5 times longer.

Lubrication requires managing, that's why I always advise sites to have a Lubrication champion who is responsible for tracking use, taking samples and working it partnership with their lubricant supplier.

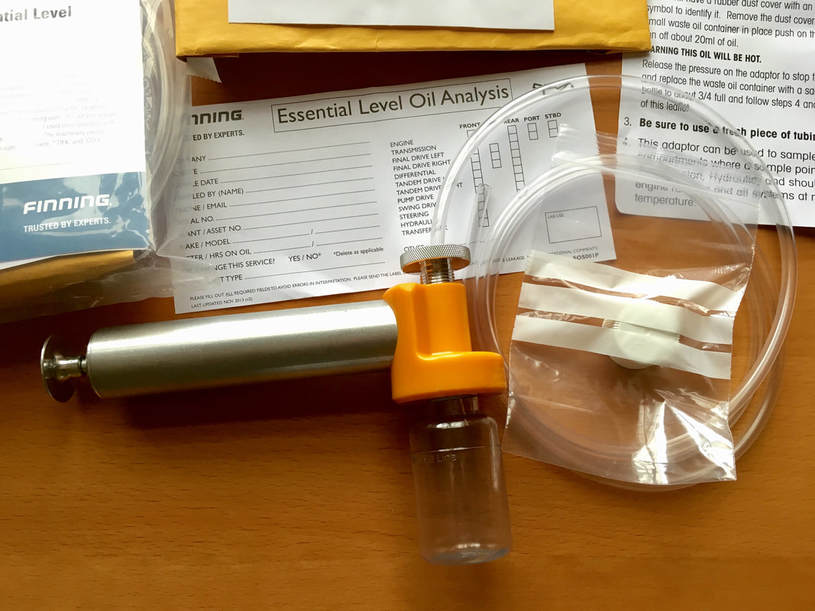

Vacuum pump is an essential item if you have no sampling ports, it needs to be used correctly to get true representative samples.

How do we go about it?

Well you can buy a Laboratory and do it yourself... but the ROI would be hard to justify.

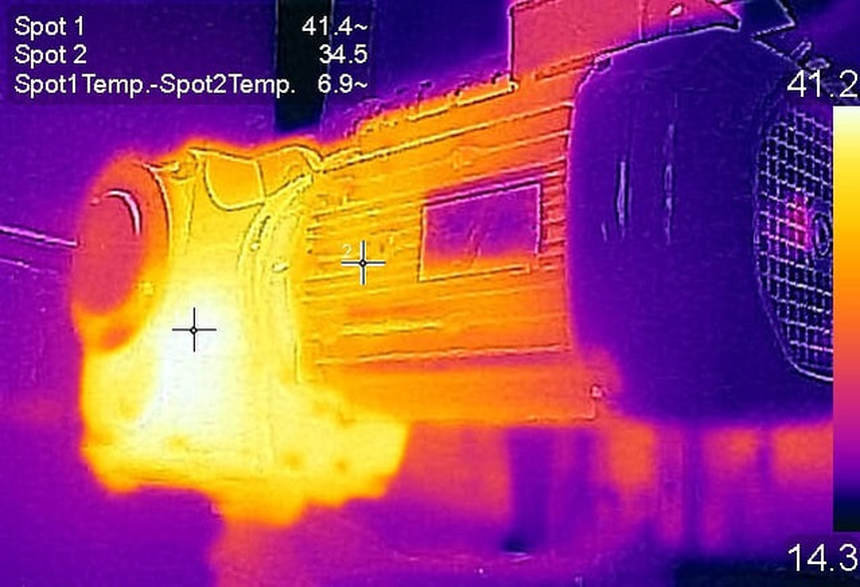

You could employ a contractor that takes Thermal, Vibration, Ultrasound and Oil Samples.

This may be a good way to start but ownership is best held eventually within the company.

Starting this way you can get the skills transferred, it's my preferred choice and one that I have used successfully before.

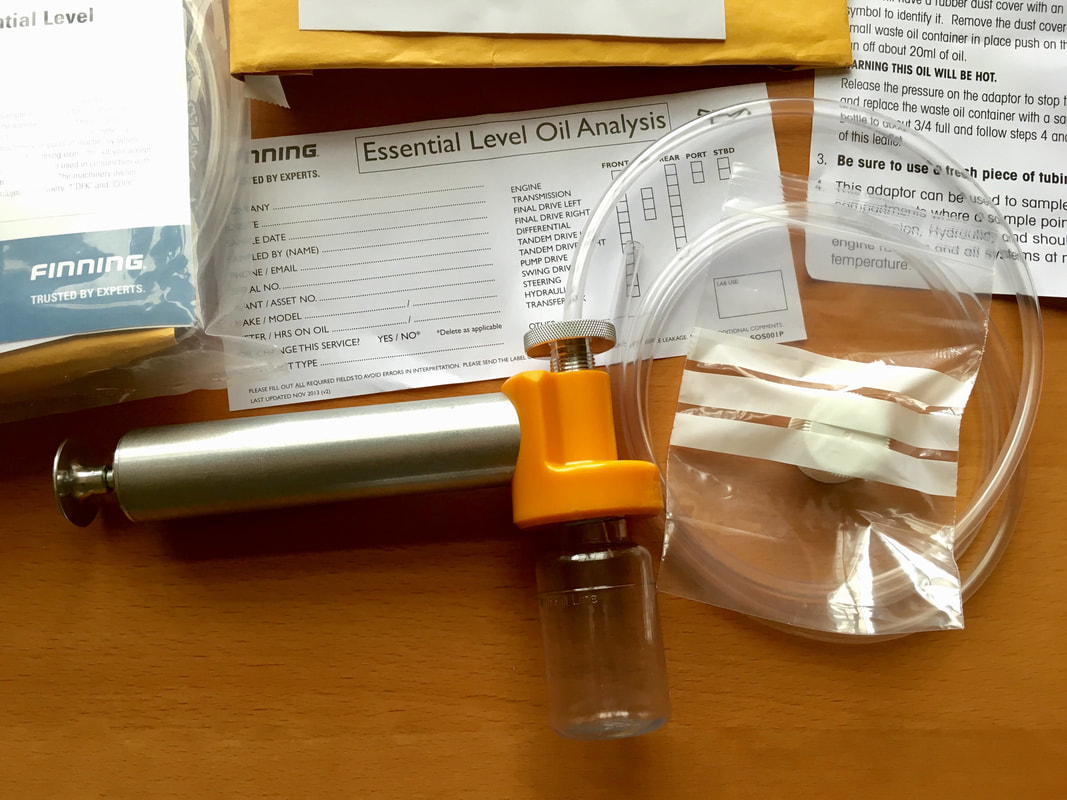

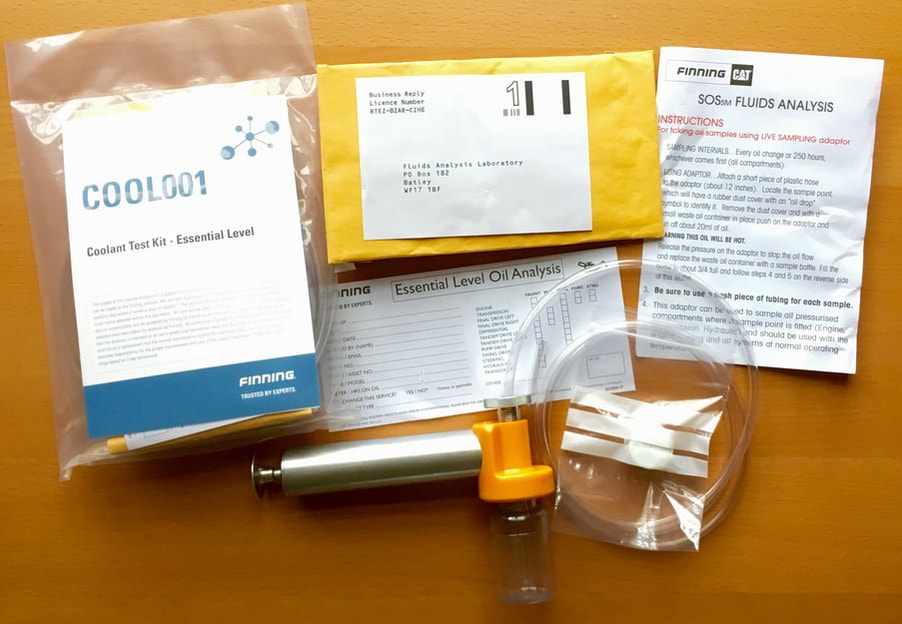

If you are going to set up an inspection process I would recommend an Oil Sampling service like CAT Finning provide.

Here you purchase a sampling kit (they also do fuel and coolant) these provide a self addressed envelope, bottle, tube and plastic closure bag to post the samples back to their laboratory.

Results are then posted via their on-line database a couple of days later.

You need to know what to look for, this is where some training may be required

Samples have to be taken in a certain way from the optimum take off points and the results need interpreting.

The laboratory will give you an idea after they have a trended database of six or more readings, but they don't live in your facility so will not always have all the information that is available to you.

If you want to talk about your oil management including service work please get in touch at: [email protected]

UPTIME Consultant run our own Oil Sampling database that can be used on your behalf if required.

We also have a free short Oil Sampling course on our UPTIME Consultant Academy®

Well you can buy a Laboratory and do it yourself... but the ROI would be hard to justify.

You could employ a contractor that takes Thermal, Vibration, Ultrasound and Oil Samples.

This may be a good way to start but ownership is best held eventually within the company.

Starting this way you can get the skills transferred, it's my preferred choice and one that I have used successfully before.

If you are going to set up an inspection process I would recommend an Oil Sampling service like CAT Finning provide.

Here you purchase a sampling kit (they also do fuel and coolant) these provide a self addressed envelope, bottle, tube and plastic closure bag to post the samples back to their laboratory.

Results are then posted via their on-line database a couple of days later.

You need to know what to look for, this is where some training may be required

Samples have to be taken in a certain way from the optimum take off points and the results need interpreting.

The laboratory will give you an idea after they have a trended database of six or more readings, but they don't live in your facility so will not always have all the information that is available to you.

If you want to talk about your oil management including service work please get in touch at: [email protected]

UPTIME Consultant run our own Oil Sampling database that can be used on your behalf if required.

We also have a free short Oil Sampling course on our UPTIME Consultant Academy®

Lubricating your Assets

Lubrication, a piece of the reliability puzzle often ignored at some cost

Talking with a prospective client managing an operation that is totally reactive in the way they handle maintenance work, it was an interesting discussion that got right to the basics of Lubrication.

When I initially visit a business I ask questions about the key functions from a productivity and engineering perspective, I then listen a lot to what is relayed.

An enquiry about Predictive Maintenance and starting a Condition Based Maintenance plan, quite quickly it was apparent that we may have to revisit those at a later date.

One subject included in any work I undertake is Lubrication, without a robust strategy for lubrication in control it is hard to move forward to predictive maintenance, this was no exception and I learnt the most from conversations on the factory floor with operators.

Lubrication was having a negative impact on the availability and reliability of their assets but nobody realised, not because anyone was incompetent, but they just never considered it and accepted their common practice.

I often amazed how lacking lubrication strategies can be, from specification, procurement, right the way through to the application in the equipment.

When I initially visit a business I ask questions about the key functions from a productivity and engineering perspective, I then listen a lot to what is relayed.

An enquiry about Predictive Maintenance and starting a Condition Based Maintenance plan, quite quickly it was apparent that we may have to revisit those at a later date.

One subject included in any work I undertake is Lubrication, without a robust strategy for lubrication in control it is hard to move forward to predictive maintenance, this was no exception and I learnt the most from conversations on the factory floor with operators.

Lubrication was having a negative impact on the availability and reliability of their assets but nobody realised, not because anyone was incompetent, but they just never considered it and accepted their common practice.

I often amazed how lacking lubrication strategies can be, from specification, procurement, right the way through to the application in the equipment.

You can understand this when you read some OEM manuals, it will describe the transport, delivery, commissioning, safety controls, operation, strip down for cleaning, sub assembly removal, procedures for maintaining, specification of spares, suggested spare parts list, then somewhere at the rear it will include two cursory pages, copied and pasted from a lubrication supplier with some pretty basic generic instructions, annual oil change, list of recommended oils etc.

Lubrication should never be an afterthought, it needs to be smarter, with specification and control to add the most value.

This stuff is at the back of the manual so it can't be that important... can it?

Lubrication should never be an afterthought, it needs to be smarter, with specification and control to add the most value.

This stuff is at the back of the manual so it can't be that important... can it?

Ignore it at your peril, I had a conversation some years ago with a contractor commissioning a new production line with his grease gun in hand, I asked a silly question and got a silly answer:

Me: "What type of grease are you using in your grease gun?"

Contractor: "Just grease"

I asked if it was H1 food standard (we were in a food factory), it was as if I was now speaking a different language by the look on his face; we then had a chat about food risks and compliance.

I lent him a grease gun with H1 grease loaded, we had a further discussion about the amount of grease he was applying to the bearings and why that was important.

The point is he was an installation contractor and he had a training gap, he didn't know he had a gap, ten minutes on the shop floor and it was solved, I wasn't teaching him to 'suck eggs' and I believe he appreciated the help.

Most of the equipment I have ever looked after has rotating elements, these can be the weak point in an overall system, this I know not just from experience but from the good work that those have done before me.

You need to understand that bearings can fail early because of a number of failure modes, the main one being over or under lubrication, some studies report as much as 80% of all bearing failures are from lubrication alone.

From my experience the failures I have witnessed have been due to too much load, heat, debris or liquid ingress. Sometimes the load and heat has been due improper mounting or to compacted grease, sometimes no grease at all, so it is important.

It's even more important when we ask our front line operators to take on the task of lubrication, it's definitely the right thing to do and I support TPM with operator training and mentoring.

In fact I would stretch that training to include the skilled trades as you don't know what you don't know!

Having formulated and implemented a Lubrication Strategy as part of a CBM plan working alongside a Predictive program, I found that one fed the other, the more outputs from the predictive tools I gathered, the more the existing lubrication could be reduced in some areas and enhanced in others.

The Predictive tools identified the lubrication risk areas, but this was just one part of a larger asset care program.

Me: "What type of grease are you using in your grease gun?"

Contractor: "Just grease"

I asked if it was H1 food standard (we were in a food factory), it was as if I was now speaking a different language by the look on his face; we then had a chat about food risks and compliance.

I lent him a grease gun with H1 grease loaded, we had a further discussion about the amount of grease he was applying to the bearings and why that was important.

The point is he was an installation contractor and he had a training gap, he didn't know he had a gap, ten minutes on the shop floor and it was solved, I wasn't teaching him to 'suck eggs' and I believe he appreciated the help.

Most of the equipment I have ever looked after has rotating elements, these can be the weak point in an overall system, this I know not just from experience but from the good work that those have done before me.

You need to understand that bearings can fail early because of a number of failure modes, the main one being over or under lubrication, some studies report as much as 80% of all bearing failures are from lubrication alone.

From my experience the failures I have witnessed have been due to too much load, heat, debris or liquid ingress. Sometimes the load and heat has been due improper mounting or to compacted grease, sometimes no grease at all, so it is important.

It's even more important when we ask our front line operators to take on the task of lubrication, it's definitely the right thing to do and I support TPM with operator training and mentoring.

In fact I would stretch that training to include the skilled trades as you don't know what you don't know!

Having formulated and implemented a Lubrication Strategy as part of a CBM plan working alongside a Predictive program, I found that one fed the other, the more outputs from the predictive tools I gathered, the more the existing lubrication could be reduced in some areas and enhanced in others.

The Predictive tools identified the lubrication risk areas, but this was just one part of a larger asset care program.

Existing Lubricant inventory was reduced by 50%, new lubrication storage was installed, specifications tightened, procurement controlled, a supplier partnership developed, technicians and operators trained, clean replenishment tools implemented, colour coding introduced, schematics produced, workplace aids posted, machines tagged, oil sampling developed, used lube oils and containers recycled, these were just some of the measures that dramatically reduced the failure rates and reactive work.

People often say to me that they find it hard to identify an ROI on lubrication, all of the above measures positively impacted the operations KPIs of safety, OEE, availability and reliability, it helped in delivering a Green scorecard for the Engineering and Maintenance function as well, it provided wins all around.

Personally I find it easy to quantify ROI for Lubrication best practices

Everything rotates and most of it relies on a microscopic wedge of lubricant to keep the wheels from falling off!

In a former life I had a manager that made disparaging remarks about my lubrication best practices... I offered to go drain the oil out of his car and see how far he got at the end of shift... I believe he received the message!

If you would like a chat about your Lubrication Strategy then give me a call or send me an email [email protected]

High Temperature Lubrication from Interflon

Read the pdf below of how HT Greases impacted critical assets in driving to zero failures

Oil Sampling... Why, What, When and Where?

Listen to Jim Fitch from Noria describe why we look for 'live zones' to take our oil samples