Vibration

Most ubiquitous of all the techniques, everybody has heard or knows of Vibration monitoring

Most people start with Vibration for a reason, or quite a few reasons actually.

Vibration as a predictive tool has been around the longest of all the five disciplines I focus on at Uptime Consultant.

Because of this history it has built up quite a following, it has recognised standards (quite a few) and the choice of equipment is sometimes bewildering. I can advise on the latest hand held or on-line permanent solutions if required.

Many Vibration experts could quite easily add another new vibration instrument to their toolbox each year and I'm sure they would still keep on coming!

Learning the fundamentals of what an asset actually does, how it behaves and then knowing if Vibration is applicable is half the battle.

Knowing what to look for in that equipment is also important, vibration is great with unbalance, mis-alignment and looseness, but like all the previously mentioned PdM techniques you get the best results through training, practice and experience.

The articles below will give you a head start with the subject, there are some great on-line resources.

Where I can help is at the front line with your assets, how to best develop and implement PdM is as important as taking readings of vibration.

Click HERE to contact me direct for a chat or quote, talking is free and if I can help I'm sure together we can save you time and money.

Vibration as a predictive tool has been around the longest of all the five disciplines I focus on at Uptime Consultant.

Because of this history it has built up quite a following, it has recognised standards (quite a few) and the choice of equipment is sometimes bewildering. I can advise on the latest hand held or on-line permanent solutions if required.

Many Vibration experts could quite easily add another new vibration instrument to their toolbox each year and I'm sure they would still keep on coming!

Learning the fundamentals of what an asset actually does, how it behaves and then knowing if Vibration is applicable is half the battle.

Knowing what to look for in that equipment is also important, vibration is great with unbalance, mis-alignment and looseness, but like all the previously mentioned PdM techniques you get the best results through training, practice and experience.

The articles below will give you a head start with the subject, there are some great on-line resources.

Where I can help is at the front line with your assets, how to best develop and implement PdM is as important as taking readings of vibration.

Click HERE to contact me direct for a chat or quote, talking is free and if I can help I'm sure together we can save you time and money.

Vibration Articles

Vibration Matters

What better way to introduce Vibration but with Jimi Hendrix a mastermind when you think about vibration as a subject. This is a bronze on the Isle of Wight where the famous festivals took place between 1968 and 1970, the last one was said to be bigger than Woodstock, it's estimated 600-700,000 people attended. 50th Anniversary Festival takes place in 2018.

When I present my 'Introduction to Predictive Maintenance' that includes Vibration I talk about the way guitar strings vibrate as most people will have held a guitar and some may have even plucked the occasional string, we can even cover resonance and sympathetic vibration.

Vibration is all around us especially when we listen to music or cause vibration in the air when we are talking to other people. It's ubiquitous just like Vibration technology that is used in Predictive Maintenance (PdM), it's probably the most widely known and used of the PdM techniques. This has many reasons including the length of time it has been used in industry, the easy access to tools, cheap sensors and many standards that apply to vibration.

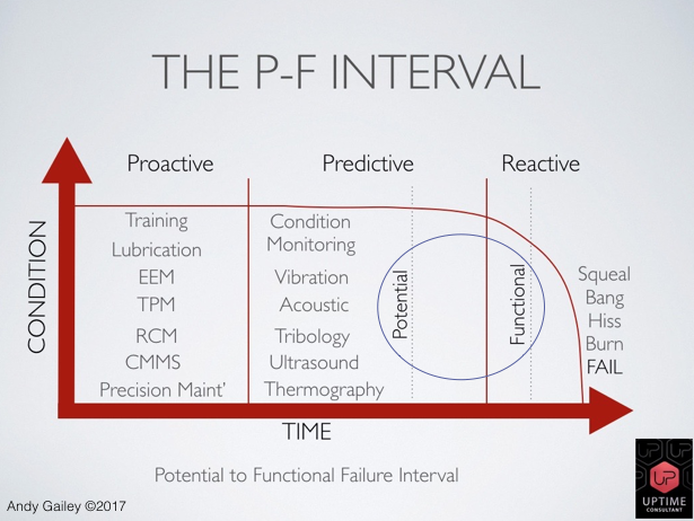

For me it's another great tool in the predictive maintenance toolbox that like all has its own strengths and weaknesses. I believe Vibration is best aimed at assets that have risks of misalignment, out of balance or looseness. If you are very experienced and have some of the higher end equipment you may be able to pick out bearing issues but we may have travelled a little further than we would like along the P-F interval in my experience.

Vibration is all around us especially when we listen to music or cause vibration in the air when we are talking to other people. It's ubiquitous just like Vibration technology that is used in Predictive Maintenance (PdM), it's probably the most widely known and used of the PdM techniques. This has many reasons including the length of time it has been used in industry, the easy access to tools, cheap sensors and many standards that apply to vibration.

For me it's another great tool in the predictive maintenance toolbox that like all has its own strengths and weaknesses. I believe Vibration is best aimed at assets that have risks of misalignment, out of balance or looseness. If you are very experienced and have some of the higher end equipment you may be able to pick out bearing issues but we may have travelled a little further than we would like along the P-F interval in my experience.

Above, the Uptime Consultant take on the P-F interval and where the predictive technologies sit.

If you are considering including Vibration in your PdM program I always advise to start small with easy to use handheld devices, this with support will get you a basic level of understanding that can be built on. It can also provide some quick, simple and cheap benefits in a short time frame with minimal investment in equipment.

Like all the PdM techniques a level of training and understanding of what is and is not achievable pays dividends in the long run. Always budget an equal amount of investment in tuition when considering the total cost of deployment, figure in similar amounts for equipment and training, a £5K instrument may require a like amount investing in training and release.

Criticality of equipment and savings in operations and maintenance should factor in the return on investment before you invest, this is important as PdM has to provide payback in the reduction of both planned and unplanned work, reducing invasive maintenance, providing asset availability whilst reducing wastes and enhancing a safe working environment.

Vibration is a PdM technique that we need to include in our toolbox for efficient data collection. It is capable of quickly confirming or dispelling suspicions of out of balance, misalignment or looseness.

Training, knowing your assets and monitoring equipment are all equally important to gain maximum benefit from your predictive maintenance program.

Like all the PdM techniques a level of training and understanding of what is and is not achievable pays dividends in the long run. Always budget an equal amount of investment in tuition when considering the total cost of deployment, figure in similar amounts for equipment and training, a £5K instrument may require a like amount investing in training and release.

Criticality of equipment and savings in operations and maintenance should factor in the return on investment before you invest, this is important as PdM has to provide payback in the reduction of both planned and unplanned work, reducing invasive maintenance, providing asset availability whilst reducing wastes and enhancing a safe working environment.

Vibration is a PdM technique that we need to include in our toolbox for efficient data collection. It is capable of quickly confirming or dispelling suspicions of out of balance, misalignment or looseness.

Training, knowing your assets and monitoring equipment are all equally important to gain maximum benefit from your predictive maintenance program.

Vibration Introduction

Vibration Technology introduction from The Mobius Institute

A great introduction to Vibration Analysis from Jason Tranter, Founder and Director of the Mobius Institute

Vibration Analysis: Diagnosing Looseness from The Mobius Institute

Learn more about Vibration and Looseness in this video from Jason Tranter