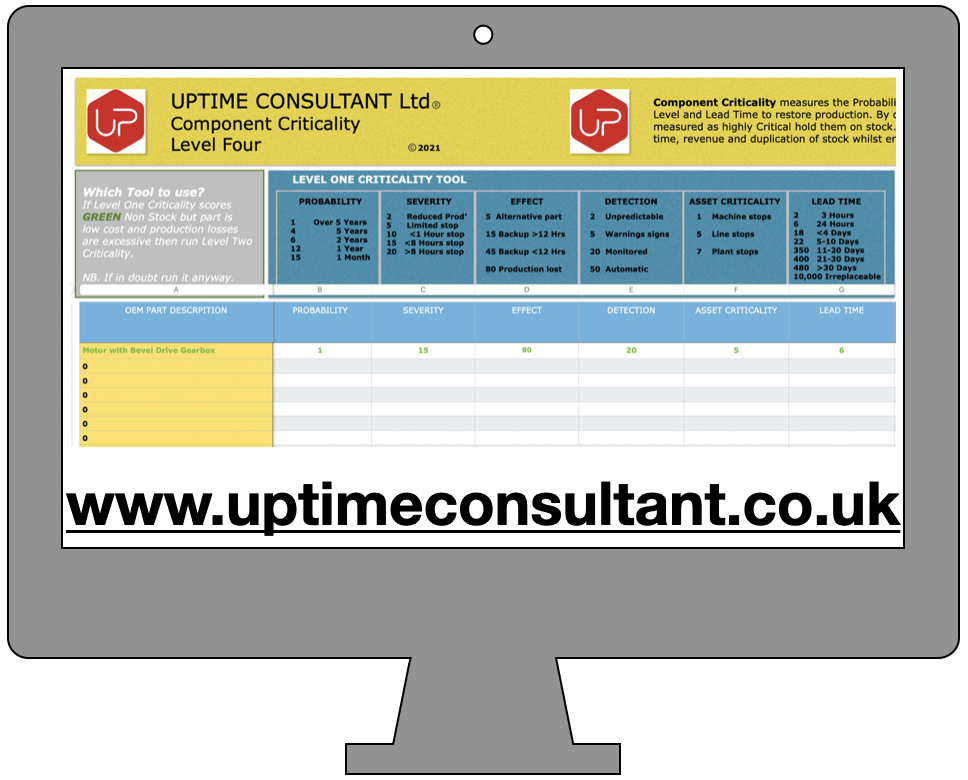

How we frame your strategy with our Criticality ProcessOne of the tools we've developed over the past few years is a 'Criticality Process' with a twist.

As soon as you mention running a Criticality Study many retort that it's too slow, too costly, and they haven't got the time. This is where UPTIME Consultant can help because our process is (relatively) quick, costs less than you save (all ours have been paid for just with inventory criticality) and we have the time to get it done by concentrating on the task in hand. We have happy customers that will vouch for the above (on request!) we even train them to use the process if they have the inclination. Our process identifies all the assets in a process (new or legacy it doesn't matter), looks at the maintainable components, takes into account OEM recommendations (not always correct), identifies the risk and consequences of failure, accounts for the client's appetite for risk, classifies the spares for stock hold, considers lead times (even more important now), identifies opportunities for proactive/predictive inspections, records Lubrication specifications, recommends maintenance instructions and tasks, highlights skills gaps, and many more aspects. This frames the business Maintenance Strategy for capital equipment, reduces the risk of failure, stocks critical items, increases visibility of aspects that were unknown at the outset. If you want to find out more please get in touch.

0 Comments

|

Andy

|

RSS Feed

RSS Feed