Ultrasound

Similar to Acoustic Emission as they both measure waves but Ultrasound is more well known

If it wasn't for a very clever innovator and engineer Reginald Fessenden there would be no AE or Ultrasound, see the article below.

Metal workers had known for centuries that materials made sounds during manufacture and Reginald was someone that was enthralled by 'unheard' sound and the theory of it moving in waves, he was right and during his time he worked on modulating and demodulating these signal waves.

Ultrasound has been the PdM technique for monitoring or listening to these higher frequencies in gases, liquids and pressurised systems.

It's also ideal to monitor electrical devices for Arcing, Tracking and Corona, all can have very damaging effects in control cabinets.

Pneumatic airlines and steam traps are another popular application as these two utilities can result in massive losses in revenue and unavailability.

The range of Ultrasound devices is expanding and becoming more affordable, like all these PdM techniques though you will only get the best results through training and directing them towards the right asset at the right time.

Click HERE to discuss your PdM training or support needs, talking costs nothing and I could save you time and money.

Metal workers had known for centuries that materials made sounds during manufacture and Reginald was someone that was enthralled by 'unheard' sound and the theory of it moving in waves, he was right and during his time he worked on modulating and demodulating these signal waves.

Ultrasound has been the PdM technique for monitoring or listening to these higher frequencies in gases, liquids and pressurised systems.

It's also ideal to monitor electrical devices for Arcing, Tracking and Corona, all can have very damaging effects in control cabinets.

Pneumatic airlines and steam traps are another popular application as these two utilities can result in massive losses in revenue and unavailability.

The range of Ultrasound devices is expanding and becoming more affordable, like all these PdM techniques though you will only get the best results through training and directing them towards the right asset at the right time.

Click HERE to discuss your PdM training or support needs, talking costs nothing and I could save you time and money.

Ultrasound Basics

Where could Ultrasound fit in your Predictive Maintenance program, find out more in this article

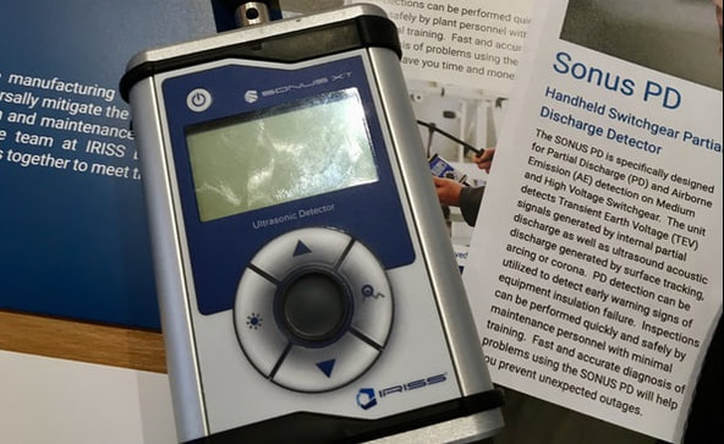

IRISS Sonus XT

Ultrasound can be used in many different applications, babies in the womb are monitored using low level frequencies, welding can be carried out using ultrasound, the aspect I will be examining here is the monitoring and inspection of physical assets in diverse industries.

If it wasn't for one man back at the turn of the twentieth century we wouldn't have this technique at all. Reginald Aubrey Fessenden was born in 1866, by the time he was 35 in 1901 he had identified a process known as Heterodyning in which two frequencies are combined to reveal another new frequency.

This signal is then processed further by modulation and demodulation, transposed in a non linear signal processor combining the two frequencies manufactures two new ones.

In Ultrasonic devices these are known as High and Low frequencies, the lower frequencies are then filtered out to highlight the High frequencies that we are most interested in.

Reginald therefore is the father of modern Ultrasound and Amplitude Modulation commonly known as AM radio.

By being able to transpose High frequency waves into Low frequency the human ear is now able to hear these important signals.

If it wasn't for one man back at the turn of the twentieth century we wouldn't have this technique at all. Reginald Aubrey Fessenden was born in 1866, by the time he was 35 in 1901 he had identified a process known as Heterodyning in which two frequencies are combined to reveal another new frequency.

This signal is then processed further by modulation and demodulation, transposed in a non linear signal processor combining the two frequencies manufactures two new ones.

In Ultrasonic devices these are known as High and Low frequencies, the lower frequencies are then filtered out to highlight the High frequencies that we are most interested in.

Reginald therefore is the father of modern Ultrasound and Amplitude Modulation commonly known as AM radio.

By being able to transpose High frequency waves into Low frequency the human ear is now able to hear these important signals.

Reginald also transmitted the first voice via radio in 1900 and the first trans atlantic conversation by radiotelegraph.

This Canadian born inventor and child genius even had his portrait on a Canadian stamp.

He received many awards due to his work and held hundreds of patents in relation to radio and sonar.

Reginald Aubrey Fessenden (Oct 6, 1866 - July 22, 1932)

Sounds outside of human audible range of 20Hz to 20,000Hz can provide valuable insights to our asset health by using this Ultrasound technology. By using the above described Heterodyning it reveals 'hidden' frequencies above the 20kHz range.

Ultrasound is a versatile technology that is particularly suited to air and fluid borne activity, this includes powders and other types of gases other than air. Care must be taken though if working in explosive atmospheres where you will need to use an intrinsically safe Ultrasound detector.

Ultrasound is a versatile technology that is particularly suited to air and fluid borne activity, this includes powders and other types of gases other than air. Care must be taken though if working in explosive atmospheres where you will need to use an intrinsically safe Ultrasound detector.

IRISS Sonus XT & Parabolic Dish

Predictive Maintenance in industrial applications including systems that are pressurised or electrical equipment is where Ultrasound can provide the maximum benefits.

For instance, compressed air as a utility is the most expensive utility of all, using Ultrasound to identify leaks in pneumatics can not only restore system volume but save waste and revenue at the same time.

Electrical panel inspections using Ultrasound can reveal harmful corona, tracking or arcing taking place, all can have detrimental effects on your asset integrity and personnel safety.

Panel inspections can now be made less invasive and safer with the use of maintenance inspection windows from IRISS, some are tested to be explosion resistant, this allows safety whilst testing by keeping the panel and enclosure doors closed.

For instance, compressed air as a utility is the most expensive utility of all, using Ultrasound to identify leaks in pneumatics can not only restore system volume but save waste and revenue at the same time.

Electrical panel inspections using Ultrasound can reveal harmful corona, tracking or arcing taking place, all can have detrimental effects on your asset integrity and personnel safety.

Panel inspections can now be made less invasive and safer with the use of maintenance inspection windows from IRISS, some are tested to be explosion resistant, this allows safety whilst testing by keeping the panel and enclosure doors closed.

Sonus XT used with CAT phone and CAP Electrical Maintenance Inspection window

Ultrasound equipment is now readily available at a number of price points to suit your budget and application. The basics are easily picked up with some tuition and practice, like all the PdM techniques though an investment in training and practical experience is key to getting the most from the equipment.

If your operation or plant room employ many pressurised systems including compressed air, other gases, steam traps and vacuums then it is worth considering making Ultrasound part of your PdM program.

Likewise if you have many electrical panel inspections to perform or have concerns about corona and tracking then Ultrasound is the PdM tool for these applications.

Uptime Consultant is Level 1 accredited in Ultrasound and can help with your initial steps towards preparing you to utilising this versatile technique.

Many thanks to IRISS for the loan of the Sonus XT and the level one training course. More details can be found at www.iriss.com or to talk further get in touch with me directly at [email protected]

If your operation or plant room employ many pressurised systems including compressed air, other gases, steam traps and vacuums then it is worth considering making Ultrasound part of your PdM program.

Likewise if you have many electrical panel inspections to perform or have concerns about corona and tracking then Ultrasound is the PdM tool for these applications.

Uptime Consultant is Level 1 accredited in Ultrasound and can help with your initial steps towards preparing you to utilising this versatile technique.

Many thanks to IRISS for the loan of the Sonus XT and the level one training course. More details can be found at www.iriss.com or to talk further get in touch with me directly at [email protected]

Arc Flash Avoidance & Solutions

My background in Engineering is production based with a large mechanical bias although I am constantly adding to my knowledge day by day, I learn something new every day and love to share the stand out stuff when I have the opportunity.

Before starting I confess the equipment I cover in this article is based on my experience, they are taken from the IRISS Inc catalogue because until I took a three day level one course in Ultrasound with them I was unaware of their products.

I already have an extensive knowledge of PdM technology as a practitioner and as a trainer, one thing I never had the opportunity to take was an Ultrasound course until IRISS offered me this chance.

In the past as a Predictive Maintenance practitioner I was interested in people and mechanical production assets, that rotated, reciprocated or slid involving bearings, motors, gearboxes, pumps, cylinders, conveyors, tracks and many other process equipment.

I had therefore only used Ultrasound for pneumatics, vacuums and other pressure devices, I had never used it for electrical inspections as I am not qualified to access electrical panels, likewise with Thermography, I rarely used it for panel inspections, only externally. The permit to work and safe operating procedures where I worked carried very high standards as the risks of electrical panel access were widely recognised and adhered to.

This Ultrasound course was even more interesting for me as IRISS have a background in electrical inspections with a long history of using thermography. As equipment has become more critical and in some cases complicated so has the need for effective predictive maintenance to flag issues before major collateral damage takes place.

Some facilities in airports and data hubs are so critical that thermal image inspection has become prescribed rather than something extra added on. This has meant more and more qualified electrical engineers have been tied up with permit to work because of restricted access, rightly so but this also means a Thermographer may spend half of his or her time awaiting accompanied access instead of inspecting the electrics in the panel.

Historically the only way to avoid opening panels to carry out thermal imaging was the installation of Infrared Windows, I knew of these devices but had never seen one fitted in an installation. As far as I knew they were always circular but I had never asked myself the question Why? Until this training course that is!

I already have an extensive knowledge of PdM technology as a practitioner and as a trainer, one thing I never had the opportunity to take was an Ultrasound course until IRISS offered me this chance.

In the past as a Predictive Maintenance practitioner I was interested in people and mechanical production assets, that rotated, reciprocated or slid involving bearings, motors, gearboxes, pumps, cylinders, conveyors, tracks and many other process equipment.

I had therefore only used Ultrasound for pneumatics, vacuums and other pressure devices, I had never used it for electrical inspections as I am not qualified to access electrical panels, likewise with Thermography, I rarely used it for panel inspections, only externally. The permit to work and safe operating procedures where I worked carried very high standards as the risks of electrical panel access were widely recognised and adhered to.

This Ultrasound course was even more interesting for me as IRISS have a background in electrical inspections with a long history of using thermography. As equipment has become more critical and in some cases complicated so has the need for effective predictive maintenance to flag issues before major collateral damage takes place.

Some facilities in airports and data hubs are so critical that thermal image inspection has become prescribed rather than something extra added on. This has meant more and more qualified electrical engineers have been tied up with permit to work because of restricted access, rightly so but this also means a Thermographer may spend half of his or her time awaiting accompanied access instead of inspecting the electrics in the panel.

Historically the only way to avoid opening panels to carry out thermal imaging was the installation of Infrared Windows, I knew of these devices but had never seen one fitted in an installation. As far as I knew they were always circular but I had never asked myself the question Why? Until this training course that is!

Left: Calcium Fluoride Infrared Windows from FLIR start at two inches diameter from about £160.

The penny dropped when I found out the 'window' is made from crystal, hence the circular nature as they are grown in petri dishes that are round, obvious!

The down side has always been the transmissibility of IR through the substrate, anyone that has a basic grasp of thermal imaging will already know that normal glass doesn't transmit and the first time you take an image of someone wearing glasses proves this with two big black lenses staring back at you.

Crystal can transmit a certain IR range but like all predictive technologies it comes with downsides, they are fragile and can easily be broken in transit fitting or in use; this rules them out of Food and Pharma industries. They are also hydroscopic so to combat this the manufacturers coat the lenses, unfortunately this coating may not cover the edge of the crystal and can become easily damaged by thermal imager's lense protectors. Over time they can fog up and become useless so have to be replaced in service. These windows can only support small diameter crystals so the field of view is limited.

Martin Robinson the CEO of IRISS was kind enough to present a company overview and how he experienced a 'how does that work' moment when looking at a simple PIR security device. His thought process was; well if that can pick up movement by IR why can't we use a similar polymer to transmit IR in an industrial window?

He didn't stop there though, he went through the process of trialling different iterations until he found the polymer that would transmit more than crystal windows and then patented it. Smart move. Click the link below for more information than you will probably ever need about this interesting subject.

Find out more here: http://www.datacentir.com/downloads/files/10_Things_You_Need_to_Know_About_Infrared_Windows.pdf

Crystal can transmit a certain IR range but like all predictive technologies it comes with downsides, they are fragile and can easily be broken in transit fitting or in use; this rules them out of Food and Pharma industries. They are also hydroscopic so to combat this the manufacturers coat the lenses, unfortunately this coating may not cover the edge of the crystal and can become easily damaged by thermal imager's lense protectors. Over time they can fog up and become useless so have to be replaced in service. These windows can only support small diameter crystals so the field of view is limited.

Martin Robinson the CEO of IRISS was kind enough to present a company overview and how he experienced a 'how does that work' moment when looking at a simple PIR security device. His thought process was; well if that can pick up movement by IR why can't we use a similar polymer to transmit IR in an industrial window?

He didn't stop there though, he went through the process of trialling different iterations until he found the polymer that would transmit more than crystal windows and then patented it. Smart move. Click the link below for more information than you will probably ever need about this interesting subject.

Find out more here: http://www.datacentir.com/downloads/files/10_Things_You_Need_to_Know_About_Infrared_Windows.pdf

Enter the IRISS Infrared Inspection Window.

Here's a VP-100 Series unit and you can see the honeycomb structure that supports the polymer film.

This is unobtrusive when the Imager is held up to the mesh.

So now you have an inspection window that is shockproof and unaffected by humidity; it can also now be deployed in the important Food and Pharma sectors.

The next blindingly obvious knock on effect is you can have windows that are not just circular, what about a square window, or a rectangle, or hexagon, in fact anything you want, within reason of course.

Below the CAP Series Infrared Window; an IRISS CAP-CT-12 that can come in steel or aluminium with a lockable security catch.

Below the CAP Series Infrared Window; an IRISS CAP-CT-12 that can come in steel or aluminium with a lockable security catch.

So what about the title Arc Flash Avoidance & Solutions?

It's becoming more evident that opening a powered panel can cause serious injury or death. Once companies know about this risk they have an obligation to put their employees and contractors out of harms way.

These devices are the solution to that risk of injury or sudden death, as Martin said in his presentation "no one can outrun an Arc Flash"

Engineering and Operations have to sit up and take notice of this technology or face possible prosecution in the event of an injury or death.

The follow on technology to these devices is Ultrasound, for an extra cost these windows can be fitted with plug in sensors for an external device to monitor and take measurements of Corona or Tracking the precursors to Arc Flash.

It's becoming more evident that opening a powered panel can cause serious injury or death. Once companies know about this risk they have an obligation to put their employees and contractors out of harms way.

These devices are the solution to that risk of injury or sudden death, as Martin said in his presentation "no one can outrun an Arc Flash"

Engineering and Operations have to sit up and take notice of this technology or face possible prosecution in the event of an injury or death.

The follow on technology to these devices is Ultrasound, for an extra cost these windows can be fitted with plug in sensors for an external device to monitor and take measurements of Corona or Tracking the precursors to Arc Flash.

In my opinion (and these articles are all my opinion, you can share yours if you wish) these are devices that encourage the safe inspection of electrical installations along with two complementary predictive maintenance technologies, they are a great step forward to preventing serious injury whilst monitoring the health of our assets.

Left: IRISS CAP unit with integrated Ultrasound sensor connected to IRISS Sonus XT and CAT phone to track and record outputs to identify Corona or Tracking, note data tag on inside of cover to record time and place system was inspected.

If you want to find out more about IRISS go to www.iriss.com