Total Productive Maintenance Matters

A Teamwork Maintenance Strategy for the next level in Productivity

TPM: another acronym for us all to remember, or an indispensable methodology to taking a production system to the next level; I believe the latter.

I always refer to it as 'Teamwork' Productive Maintenance as it's all about the people for me, working together in an organised way. I first heard of TPM from the Toyota Production System that utilised teamwork to achieve outstanding levels of efficiency and productivity.

Whilst it would be lovely to emulate the success of Toyota by using this methodology I believe that many have tried (Ford) and few if any have succeeded; we may be able to steal a little of the TPM process to fit our organisation though.

So what's it all about?

People working together in small diverse teams is found to provide the best results.In a maintenance centred team this means front line operators working in partnership with maintenance personnel and specialists in a collaborative atmosphere.

By working as an integrated team with a common purpose those involve are more committed to working towards a positive outcome. All organisations will not have the size of a "Toyota" and one TPM size does not fit all so some tailoring to fit will have to be employed. For some the processes TPM may not even be applicable to their business. I'm thinking about production based industry here.

The aspect of inclusion, continuous improvement and learning is something that is key and is best realised in this excellent quote from W. Edwards Deming:

I'm not a purist when it comes to these methods so I believe in mixing and matching to suit the organisations needs but some drivers have to be clarified. The organisations aims and operational goals have to be central to the TPM teams operation acting as an autonomous unit within the production process.

It has some guides laid down as foundations to operate within:

- Eliminate machine and asset losses to maximise productivity and OEE

- Allow Operators to Own the equipment with training, involvement and maintenance

- Continuous Improvement activities involving operators, maintenance and engineers

- Asset Management Strategy: review the equipment for maintainability, ease of operation, accessibility and waste reduction, above all action the deficiencies.

- Empowered Teams: autonomous teams working and acting together within guidelines to achieve overall mission goals.

- Planning and Scheduling: making sure the maintenance resource is managed whilst taking into account the process needs, looking for opportunities to act.

- Systems and Standard Procedures: document, edit and improve Standard Operating Procedures (SOPs) so that any improvements are sustainable.

- Measure and Demonstrate: progress seen through visuals, noticeboards and other methods to track the path to the operations overall mission goal.

- Continuous Improvement: teams constantly searching, testing, implementing process or maintenance improvements and solutions continuously.

- Process Reviews: whilst all these improvements and changes take place the processes of planning, maintenance with new processes on an ongoing basis.

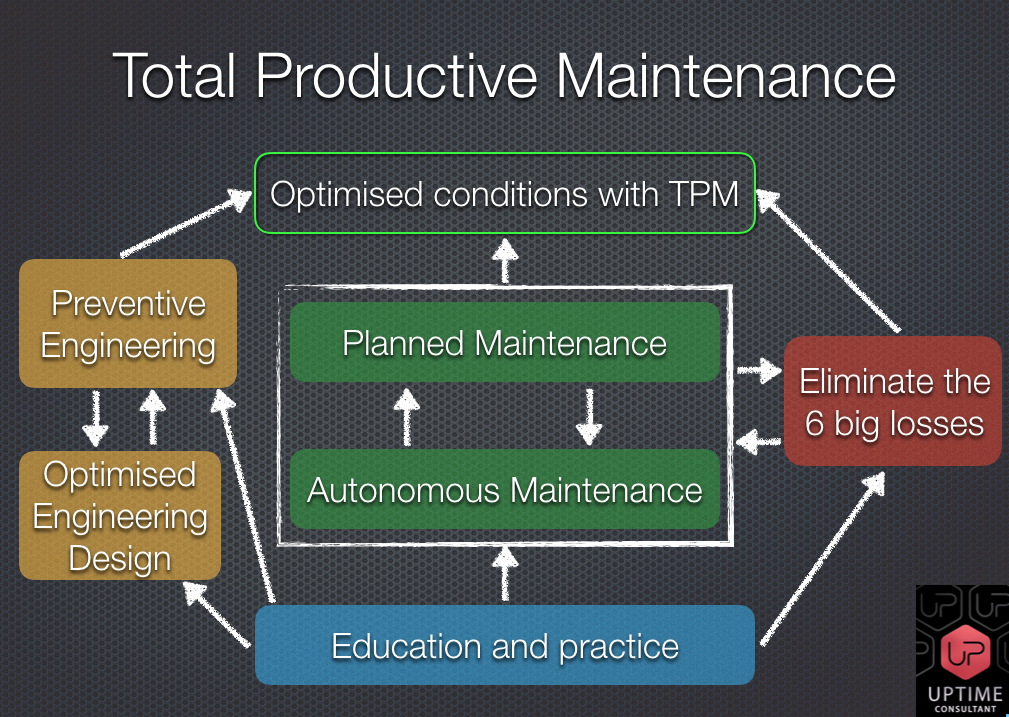

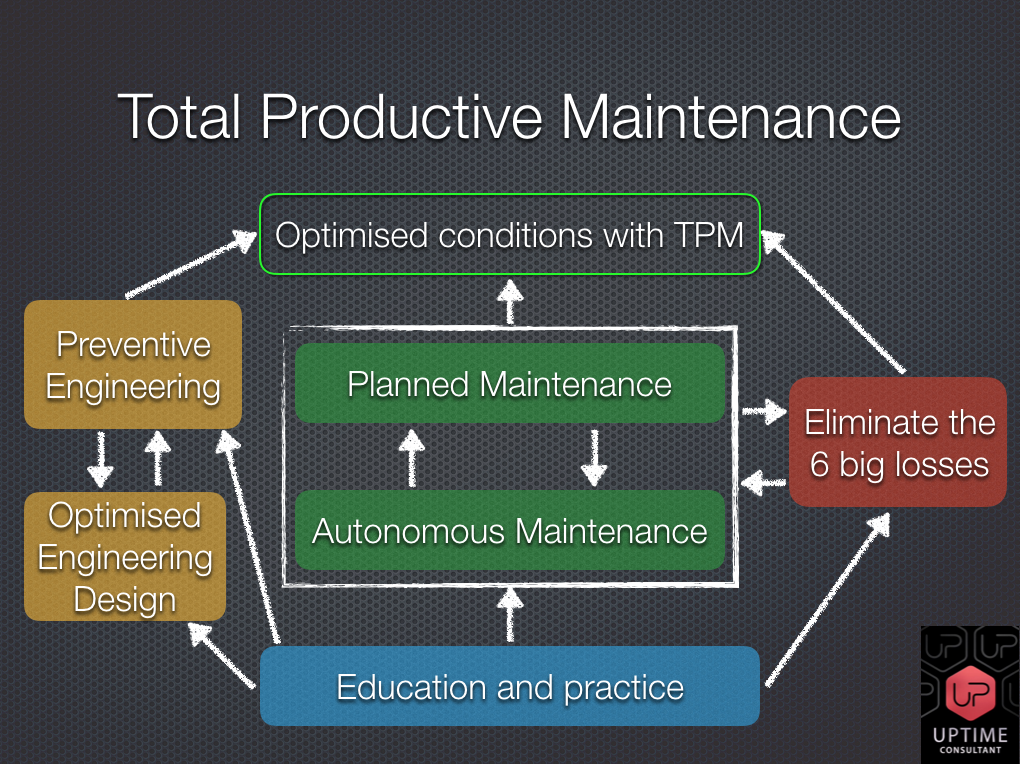

TPM infographic above from Uptime Consultant Ltd ©2017

The value of teamwork cannot be denied and is demonstrated from field sports, armed forces and in industry. Blurring the boundaries between Operators, Maintenance, Engineering and Operations is the way forward in industry, if your business is not already adopting this method it may have to soon or become unsustainable in the long term.

We can't all be Toyota but we may be able to steal a little of their methodology for our own benefit.

I hear recently that even they are looking at ripping up the rule book to reinvent the company, something Toyota have demonstrated working for them in the past.

We can't all be Toyota but we may be able to steal a little of their methodology for our own benefit.

I hear recently that even they are looking at ripping up the rule book to reinvent the company, something Toyota have demonstrated working for them in the past.

Autonomous Maintenance (AM)

Examining the relationship between AM and TPM

We can't really consider AM without understanding a TPM strategy because they are so closely intwined with each other. Autonomous Maintenance for me is where the real benefits in front line engagement, owning the equipment and the operating area exists.

Unfortunately there still exists a gap in what senior management may believe is a 'worker' to what TPM and AM knows an 'operator' is capable of. Notice the distinction here from mere worker to engaged operator. This is where the culture of a company has to shift at all levels, from workers to continuously improving and engaged operators taking care of their assets.

In todays climate of ever increasing complexity of equipment and shortage of Engineers to maintain those assets it becomes even more important to nurture empowered front line operators.

These are the only people that work with their assets day in day out that have the knowledge and ability to fill that increasing skills gap. The good news is that operations that do will benefit on multiple levels, from increased morale, improved visibility of uptime with a happy engaged workforce.

I come at this subject with a bias and feel I must reveal my hand before I go any further. You see, I'm an advocate, I can't flip flop on this one, but it's up to the reader to make their choice. I have witnessed it in practice, the development process, some hurdles along the way, usual set backs and the adoption into a successful strategy.

It's not a race, like all good things it takes time to develop, and I would like to point out this is not a 'project', it should become part of the everyday routine that morphs over the long term to fit your particular process or operation. Continuous Improvement is part of the journey.

The infographic above is one I use in a training overview of TPM and AM to describe where it sits within the overall strategy.

There are loads of books (my favourite is 'Autonomous Maintenance in Seven Steps' by Tajiri & Gotoh) and publications out there that will explain the 6 or 7 step programs of autonomous maintenance, so I'm not going to copy and paste all that here.

Here I attempt to explain how I personally have experienced AM working in practice

My experience is from ten years spent as part of a reliability team implementing a Condition Based Monitoring and Lubrication strategy for a large food site. I was fully hands on at this activity and nearly all of the Condition Monitoring (CM) was route based with handheld technology. AM was a new part of the strategy at the time but was having those early adoption difficulties, I learnt very early on that the last thing I needed to do was blindly take CM route readings; there was great information already out there.

For me if there's no benefit in doing something then you need to move on, in all the years I performed CM my best 'tool' was the Operator that was looking after the particular production line of interest. These were my 'go to people' that held a wealth of invaluable information, the dicotomy was they didn't know until we talked about their equipment and their thoughts.

So that's how I personally developed my own network on the front line of 'eyes and ears' for Condition Monitoring. Out of that group emerged some key people who were what I referred to last week as my 'change merchants', these were the operators that within a couple of months would search me out to tell me of issues they had either seen, heard or suspected. I actively worked with them to go out and show them if their suspicions were founded by involving them in using some of the CM tools. More often than not their suspicions were confirmed as parts were proved to be showing early signs of degradation or breakdown.

These were also the operators that later on took readily to up skilling with Lubrication training being a great start to their future development.

For me if there's no benefit in doing something then you need to move on, in all the years I performed CM my best 'tool' was the Operator that was looking after the particular production line of interest. These were my 'go to people' that held a wealth of invaluable information, the dicotomy was they didn't know until we talked about their equipment and their thoughts.

So that's how I personally developed my own network on the front line of 'eyes and ears' for Condition Monitoring. Out of that group emerged some key people who were what I referred to last week as my 'change merchants', these were the operators that within a couple of months would search me out to tell me of issues they had either seen, heard or suspected. I actively worked with them to go out and show them if their suspicions were founded by involving them in using some of the CM tools. More often than not their suspicions were confirmed as parts were proved to be showing early signs of degradation or breakdown.

These were also the operators that later on took readily to up skilling with Lubrication training being a great start to their future development.

When I think about it now these individuals realised as much as my CM technology did, back then I would start an inspection by taking five or ten minutes with the operators talking about the process, how were things going, had they noticed anything unusual, were there any product issues, what were the process set points doing, had they any suspicions of impending issues. This not only enhanced my process knowledge but let them realise the correlation between the equipment they were operating and the product we were producing, they also felt valued at being involved.

I was able to mentor them week on week by turning those finds we had together into preventative work orders that they then had the opportunity of actioning during planned maintenance. It took a while as all things do, it was a journey that each individual approached slightly differently, some found it easy whilst others needed more support.

That's my story on why I'm a believer in TPM and AM by bringing operators along on the journey into real ownership of their assets.

You can go and follow the prescribed 7 Steps and other plans but at the end of the day you have to interact with people, mentor your front line operators, share your knowledge, listen to what they are saying and learn from their experience.

These are the most valuable people in any production operation to enhance asset availability and uptime.

At the end of the day it's all about your people.

I was able to mentor them week on week by turning those finds we had together into preventative work orders that they then had the opportunity of actioning during planned maintenance. It took a while as all things do, it was a journey that each individual approached slightly differently, some found it easy whilst others needed more support.

That's my story on why I'm a believer in TPM and AM by bringing operators along on the journey into real ownership of their assets.

You can go and follow the prescribed 7 Steps and other plans but at the end of the day you have to interact with people, mentor your front line operators, share your knowledge, listen to what they are saying and learn from their experience.

These are the most valuable people in any production operation to enhance asset availability and uptime.

At the end of the day it's all about your people.