Acoustic Emission

Not the audible range up to 20kHz but above is what we are interested in here

The technique of Acoustic Emission (AE) is one where I have a lot of experience applying with rotating equipment in automotive, food, and utilities sectors with multiple examples of proven cost benefits.

AE technology is transferrable to any industry that operates rotating equipment, it is compliant to very low speed rotation and can be used to monitor pressure systems very similar to Ultrasound.

Ultrasound and AE are close twins, but not identical

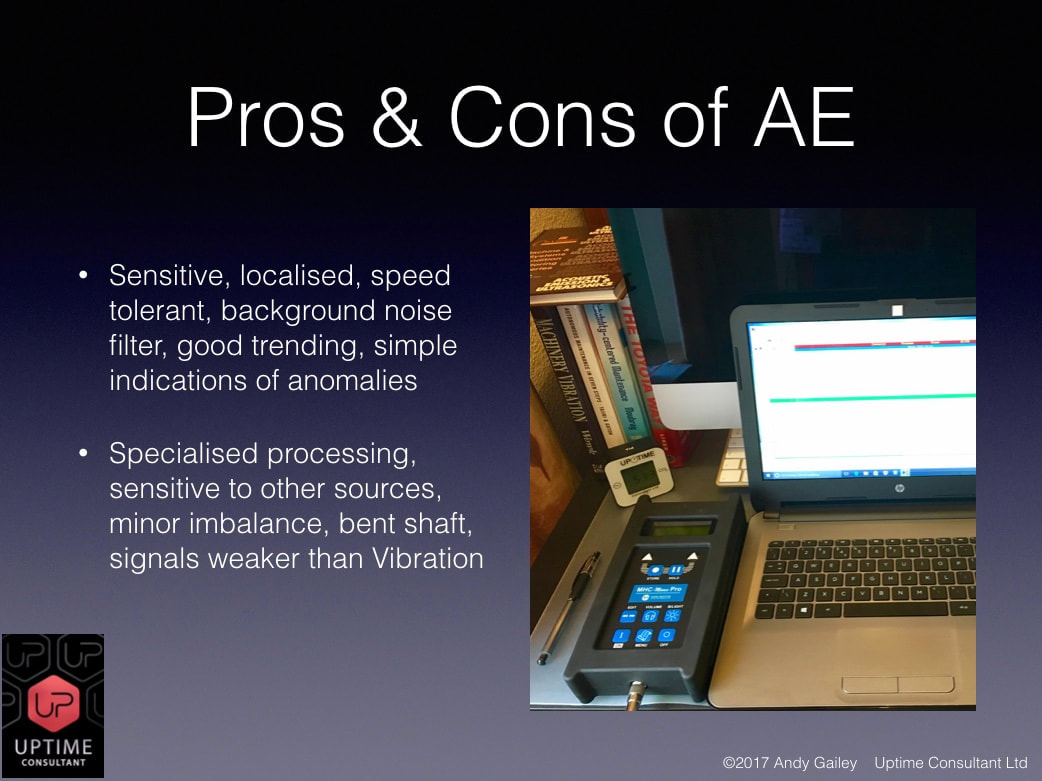

The AE instrumentation I use is the Holroyd MHC Memo Pro, it's a simple data-logger that can be used by engineers, maintainers and front line operators. UPTIME Consultant owns multiple sets that can be demonstrated on request.

I have experience of training Predictive Specialists, Reliability Engineers, Technicians, Maintainers, and Operators how to use these AE data-loggers, including aspects of asset criticality, obtaining meaningful readings, forming inspection routes, use of trending software, signature triggers, and Spectrum Analysis (FFT) if required.

The UPTIME Consultant articles below explain more about the little understood predictive technology of AE.

You can contact me direct at: [email protected] for more information about training or a proposal.

AE technology is transferrable to any industry that operates rotating equipment, it is compliant to very low speed rotation and can be used to monitor pressure systems very similar to Ultrasound.

Ultrasound and AE are close twins, but not identical

The AE instrumentation I use is the Holroyd MHC Memo Pro, it's a simple data-logger that can be used by engineers, maintainers and front line operators. UPTIME Consultant owns multiple sets that can be demonstrated on request.

I have experience of training Predictive Specialists, Reliability Engineers, Technicians, Maintainers, and Operators how to use these AE data-loggers, including aspects of asset criticality, obtaining meaningful readings, forming inspection routes, use of trending software, signature triggers, and Spectrum Analysis (FFT) if required.

The UPTIME Consultant articles below explain more about the little understood predictive technology of AE.

You can contact me direct at: [email protected] for more information about training or a proposal.

Acoustic Emission saves another critical asset just in time

On of the benefits of using a Predictive Technology as part of a holistic Reliability Strategy

It's always good to have examples that demonstrate the way joined up thinking and collaboration returns maximum benefits. This one explains the mitigation of future failures along with the wider benefits delivered.

The first line of defence in your industrial plant are operators, they spend most of their working lives with these assets producing the products that pay all of our wages.

If you are starting a predictive program, make sure you include everyone, identify individuals that notice things more often than others, talk regularly about how their process is running, and anything unusual happening with the product.

This information can sometimes reveal hidden issues that technology can't identify.

It was an operator that mentioned an unusual 'surge' sound coming from a large extruder, that lead us to examine ingredient throughputs and ruled out the process variables. Sometimes ingredient could 'bridge' causing issues with the mix into the barrel of the extruder, I could still consider this, but put it to the back of my mind.

This asset was a twin screw extruder that cooked a snack food half product; this is a pellet like dry pasta that is cooked later to produce the final savoury snack. Criticality was high on this asset as it and the sister extruder were the only two that produced this product in Europe. Disruption to this equipment would reduce availability in the supply chain causing a chain reaction of ramifications, not only in plant but across the entire customer base. Some customers will reallocate shelf space in their supermarkets if a product is not available due to disruption or shortage of supply, it's can be a nightmare to retrieve lost shelf space.

The first line of defence in your industrial plant are operators, they spend most of their working lives with these assets producing the products that pay all of our wages.

If you are starting a predictive program, make sure you include everyone, identify individuals that notice things more often than others, talk regularly about how their process is running, and anything unusual happening with the product.

This information can sometimes reveal hidden issues that technology can't identify.

It was an operator that mentioned an unusual 'surge' sound coming from a large extruder, that lead us to examine ingredient throughputs and ruled out the process variables. Sometimes ingredient could 'bridge' causing issues with the mix into the barrel of the extruder, I could still consider this, but put it to the back of my mind.

This asset was a twin screw extruder that cooked a snack food half product; this is a pellet like dry pasta that is cooked later to produce the final savoury snack. Criticality was high on this asset as it and the sister extruder were the only two that produced this product in Europe. Disruption to this equipment would reduce availability in the supply chain causing a chain reaction of ramifications, not only in plant but across the entire customer base. Some customers will reallocate shelf space in their supermarkets if a product is not available due to disruption or shortage of supply, it's can be a nightmare to retrieve lost shelf space.

End consumers would also be unhappy if they couldn't eat their favourite snack food!

The two extruders were monitored weekly with Acoustic Emission (AE) using a Holroyd MHC Memo Pro.

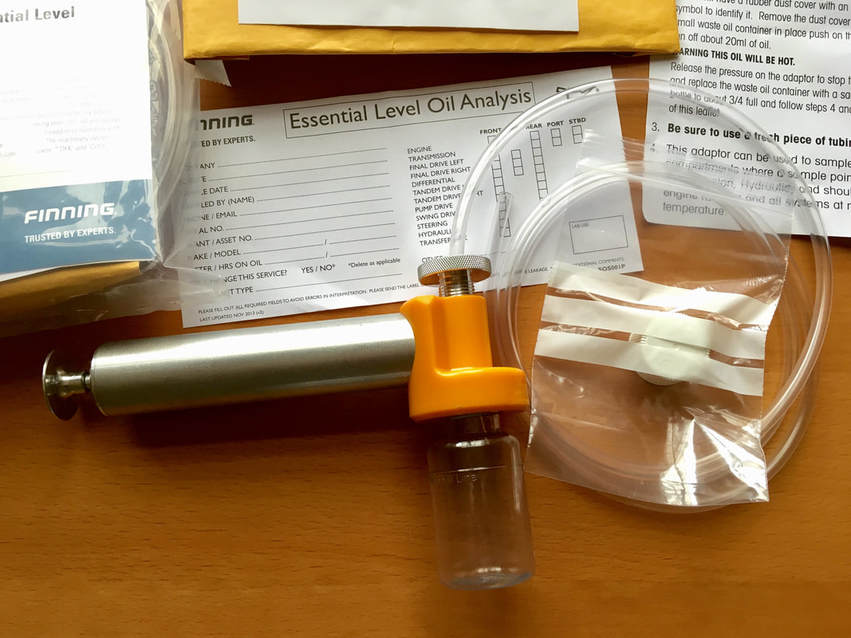

I also sampled the lubricant every month through a port, a laboratory then analysed and tracked the condition of the oil.

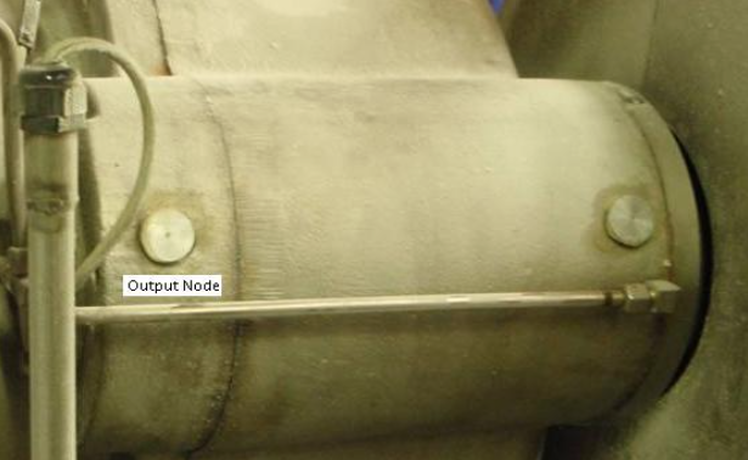

Various points on these assets were identified with 'Nodes' for repeatability as shown below.

I also sampled the lubricant every month through a port, a laboratory then analysed and tracked the condition of the oil.

Various points on these assets were identified with 'Nodes' for repeatability as shown below.

Next I interrogated the oil sample history and trends of the AE outputs over the past few months.

There had been no warnings previously, the review revealed no anomalies, some may have left it at that but I trusted what the operator had reported and I understood the asset's history.

Another key thing, 'Know Your Asset'.. the more you know the better.

I knew this extruder was 18 months older than the other and had been in service for 11 years.

I also knew it had never suffered a failure or refurbishment, we were well into the asset life cycle and we understood it had been well looked after.

I decided to take an ad hoc Oil Sample and send it to the laboratory.

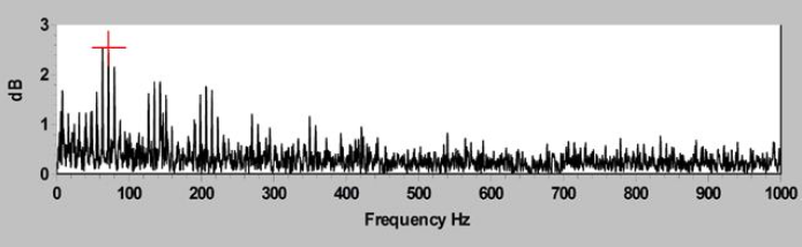

I also moved to the next level with the AE inspection, taking Spectra samples from the main gearbox and the transfer gearbox housing; this transfer was a 5:1 step down transmission that coupled the drive motor to the twin screw main extruder gearbox.

Finning Oil sample pack shown below:

The oil sample would take 3-4 days in the post, I 'phoned the laboratory requesting they expedite the sample, it was available on the database result within 48 hours, it showed an elevated Fe (Iron) reading but nothing too alarming.

I scheduled to take more frequent samples at weekly intervals.

The Spectra result was more interesting, it showed a peak indicating a possible anomaly at the inner race frequency.

The Holroyd also has the option of using headphones to observe specific points of interest, something I rarely used unless lubricating bearings in operation, you can get an excellent measure the correct volume of grease using this method.

This audio inspection indicated an intermittent 'click' occurring at a sub rotational speeds.

Another aspect about Predictive is shout about it!

I now had evidence that the asset required remedial action in the near future, emails and conversations were held with the operations manager, production specialist, maintenance/engineering managers, maintenance planner, and our off site refurbishment partners.

Everyone had a heads up... so we put a plan in place

My focus was running the Predictive and Lubrication program, for me it always included planning the best way forward, considering the whole operation, and in some cases considering re-engineering.

Another key benefit of Predictive is driving improvement, engineering change by evidence not hearsay.

Having access to the asset manual in our library I knew the original specification, could identify the SKF Bearing type without having to guess values to put into the software. I also advised the refurbisher to purchase two of these SKF Explorer bearings on our behalf to replace the input and output at the same time, they also visited the site to work on a plan to turn this transmission around within a 12 hour period, we planned on using the 48 hour sanitation and maintenance window.

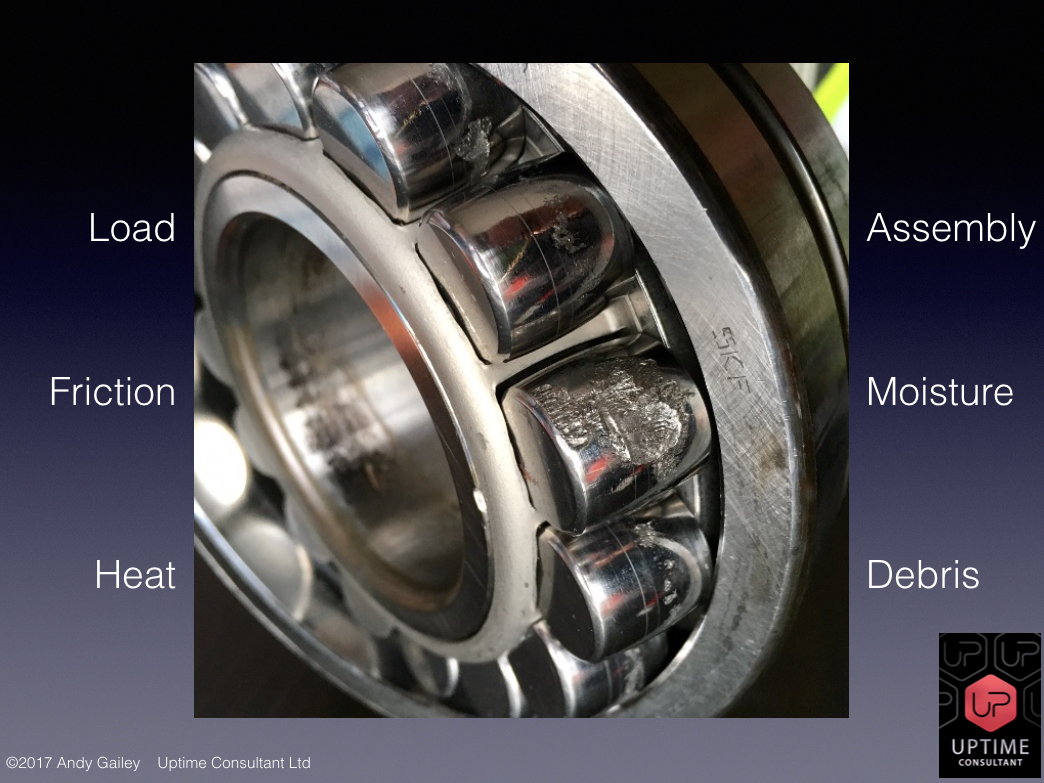

I contacted our bearing partner SKF to work together on the RCA when I had the used parts in hand, our rebuilder photographed the parts on disassembly for more evidence.

Two weeks later the transmission was removed, shipped, repaired and re-installed with no issues.

The main gearbox was flushed (both units used the same lubricant) and I checked filter patches for any debris.

The used bearings were returned so that I could clean, disassemble and inspect.

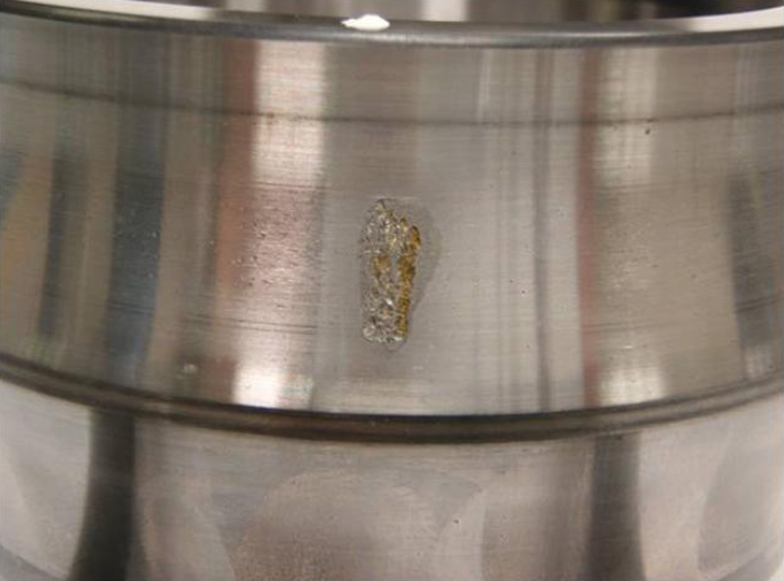

I photographed the spalling damage that had occurred on the inner race, I discussed it further with SKF when we had more information, see below.

Another key benefit of Predictive is driving improvement, engineering change by evidence not hearsay.

Having access to the asset manual in our library I knew the original specification, could identify the SKF Bearing type without having to guess values to put into the software. I also advised the refurbisher to purchase two of these SKF Explorer bearings on our behalf to replace the input and output at the same time, they also visited the site to work on a plan to turn this transmission around within a 12 hour period, we planned on using the 48 hour sanitation and maintenance window.

I contacted our bearing partner SKF to work together on the RCA when I had the used parts in hand, our rebuilder photographed the parts on disassembly for more evidence.

Two weeks later the transmission was removed, shipped, repaired and re-installed with no issues.

The main gearbox was flushed (both units used the same lubricant) and I checked filter patches for any debris.

The used bearings were returned so that I could clean, disassemble and inspect.

I photographed the spalling damage that had occurred on the inner race, I discussed it further with SKF when we had more information, see below.

In this case the asset was 'saved' and we lost no availability, but what else did this Predictive intervention deliver?

The last point is most pertinent, as I said earlier this was the 'older' of the twin screw extruders, the other was 18 months younger. My attention was now drawn to this, two years later I picked up a similar anomaly on the output bearing that lead to a similar intervention that avoided another unplanned event.

The conclusion working with SKF was that the bearings had reached their end of life (>10yrs) due to an age related mode of failure. Considering the load, environment and stresses they were under I believe they did remarkably well.

I will conclude with these thoughts that I share when training others:

Always listen to your front line operators, use multiple technologies if available, known your assets, keep your manuals in good order, talk to your rebuilders, make sure the planners for maintenance and operations are in the picture, think holistically about the impacts on internal and external customers, make operations understand that you deliver their availability, run RCA process even when there are no losses, consider redesign if necessary, record and share everything, shout about the risks and the wins, the list goes on... the benefits are multiple.

My experience with this incident allowed Operations and Engineering to grow closer in their respect for each other working as a team with a common goal.

- Avoided unplanned disruption to the process

- Technician labour used as planned not reactive

- Planned work is safer than working reactively

- Collateral damage to the main gearbox avoided

- Resulted in zero product shortages across the supply chain

- Involved the front line operators in the Predictive activity

- Demonstrated the value of the Predictive and Lubrication Program

- Involved Engineering and Operations working together with a shared goal

- Increased my knowledge of bearing life cycles working with SKF

- Instigated RCA that gave us more information

- Built confidence in the Engineering function from the Operations team

- Used a cross functional team to avoid a future catastrophic event

- Improved our knowledge of these assets for future reference

The last point is most pertinent, as I said earlier this was the 'older' of the twin screw extruders, the other was 18 months younger. My attention was now drawn to this, two years later I picked up a similar anomaly on the output bearing that lead to a similar intervention that avoided another unplanned event.

The conclusion working with SKF was that the bearings had reached their end of life (>10yrs) due to an age related mode of failure. Considering the load, environment and stresses they were under I believe they did remarkably well.

I will conclude with these thoughts that I share when training others:

Always listen to your front line operators, use multiple technologies if available, known your assets, keep your manuals in good order, talk to your rebuilders, make sure the planners for maintenance and operations are in the picture, think holistically about the impacts on internal and external customers, make operations understand that you deliver their availability, run RCA process even when there are no losses, consider redesign if necessary, record and share everything, shout about the risks and the wins, the list goes on... the benefits are multiple.

My experience with this incident allowed Operations and Engineering to grow closer in their respect for each other working as a team with a common goal.

If you are interested in booking a training course introducing Predictive, Lubrication, RCM or Reliability Strategies, either onsite or supported virtually on-line then please contact me directly at: [email protected]

Acoustic Emission (AE) the earliest warning of Potential Failure in Prediction?

Acoustic Emission, is not the noise we can hear.

This is structural borne 'noise' from the earliest inception of component wear.

So why isn't it more widely used in Industry?

This is structural borne 'noise' from the earliest inception of component wear.

So why isn't it more widely used in Industry?

Acoustic Emission is a little known technology in the industrial predictive field, this article aims to explore the basics of 'how it works', and the pragmatic, practical side of its use in Industry without getting too technical.

The slides here are from UPTIME Consultant's "Introduction to Condition Monitoring" used to train front line operators, engineers, technicians and maintenance teams; this is a full day session that includes hands on with instruments and time in your production areas to identify anomalies on the spot.

If you are reading this then you probably already know the importance of prediction and the positive impact it can have on availability, reduced unplanned downtime and less reactive work are just the tip of the iceberg.

Implemented correctly predictive tools will serve you well, most have heard of Vibration and Ultrasound but less will know about AE. There is a reason for this that I will cover later.

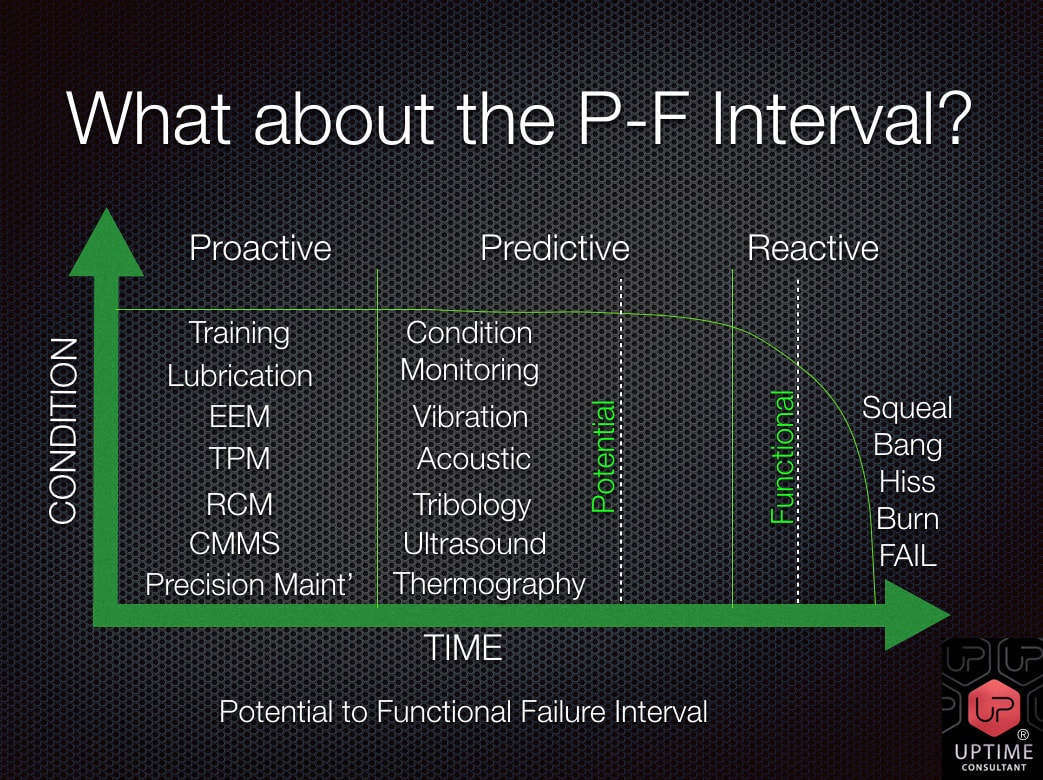

So where do the Predictive technologies sit in the grand scheme of things?

See the slide below:

The slides here are from UPTIME Consultant's "Introduction to Condition Monitoring" used to train front line operators, engineers, technicians and maintenance teams; this is a full day session that includes hands on with instruments and time in your production areas to identify anomalies on the spot.

If you are reading this then you probably already know the importance of prediction and the positive impact it can have on availability, reduced unplanned downtime and less reactive work are just the tip of the iceberg.

Implemented correctly predictive tools will serve you well, most have heard of Vibration and Ultrasound but less will know about AE. There is a reason for this that I will cover later.

So where do the Predictive technologies sit in the grand scheme of things?

See the slide below:

Slide shows where the Predictive technologies (or tools) sit in the lifecycle of our assets, the trick is to identify evidence before the 'Potential' or within the P-F interval. The five disciplines listed are covered in UPTIME Consultant's training.

AE like all Predictive disciplines augments a human sense, in this case hearing

Human hearing has a range of 20Hz to 20kHz, the frequencies we are interested in are 20kHz and above.

Condition Monitoring starts in the audible range, as we move around or operate assets our hearing picks up differences in how these machines sound, when we work with them every day we take notice... if we are taught to listen!

Our hearing is also a great way to start thinking about how we deploy Acoustic Emission.

One thing to clear up is that AE is not Vibration or Ultrasound.

I often see people get confused as Vibration has waves and sound is transmitted by sound waves.

In fact all the predictive technologies involve types of 'waves'.

AE refers to structural borne 'sound' waves outside of our hearing range.

Ultrasound is a very close relation but has more to do with fluid and airborne inspection, pneumatics, steam traps, pressure vessels, valves, arcing, discharge and tracking in electrical equipment.

Some Ultrasound equipment is now being marketed for bearing inspections... but it's still not AE.

The other thing to set straight is that AE uses Transducers that are not the same as a Vibration Accelerometer.

Acoustic Emission has been known for hundreds if not thousands of years, metals that 'sing' or 'cry' under stress has been understood by tinsmiths and metal workers. In the late 1940s with the advent of high frequency sensors and amplifiers we were able to 'listen' to these materials 'crying' under load.

Josef Kaiser was the researcher who published his thesis in 1950 reporting that materials under stress emit low amplitude 'clicks', this lead to a new NDT (Non Destructive Testing) branch called Acoustic Emission.

It has uses not just in metallic engineered structures but also in large concrete vessels and civil engineering applications including bridges, dams, motorway flyovers, silos, and pipelines where whole structures can be monitored.

In fact this is where you will find AE is more wide spread and understood.

My interest is in process equipment in production facilities, utilities, and manufacturing.

Breakdown in rotating or sliding surfaces is triggered by a number of modes of failure, including lack of lubrication allowing surfaces to clash or rub, too much lubrication causing stick slip and other effects, excessive heat, ingress of water or other harmful chemicals, excess loads, environmental issues with dirt and debris, poor quality parts or sub standard assembly.

Condition Monitoring starts in the audible range, as we move around or operate assets our hearing picks up differences in how these machines sound, when we work with them every day we take notice... if we are taught to listen!

Our hearing is also a great way to start thinking about how we deploy Acoustic Emission.

One thing to clear up is that AE is not Vibration or Ultrasound.

I often see people get confused as Vibration has waves and sound is transmitted by sound waves.

In fact all the predictive technologies involve types of 'waves'.

AE refers to structural borne 'sound' waves outside of our hearing range.

Ultrasound is a very close relation but has more to do with fluid and airborne inspection, pneumatics, steam traps, pressure vessels, valves, arcing, discharge and tracking in electrical equipment.

Some Ultrasound equipment is now being marketed for bearing inspections... but it's still not AE.

The other thing to set straight is that AE uses Transducers that are not the same as a Vibration Accelerometer.

Acoustic Emission has been known for hundreds if not thousands of years, metals that 'sing' or 'cry' under stress has been understood by tinsmiths and metal workers. In the late 1940s with the advent of high frequency sensors and amplifiers we were able to 'listen' to these materials 'crying' under load.

Josef Kaiser was the researcher who published his thesis in 1950 reporting that materials under stress emit low amplitude 'clicks', this lead to a new NDT (Non Destructive Testing) branch called Acoustic Emission.

It has uses not just in metallic engineered structures but also in large concrete vessels and civil engineering applications including bridges, dams, motorway flyovers, silos, and pipelines where whole structures can be monitored.

In fact this is where you will find AE is more wide spread and understood.

My interest is in process equipment in production facilities, utilities, and manufacturing.

Breakdown in rotating or sliding surfaces is triggered by a number of modes of failure, including lack of lubrication allowing surfaces to clash or rub, too much lubrication causing stick slip and other effects, excessive heat, ingress of water or other harmful chemicals, excess loads, environmental issues with dirt and debris, poor quality parts or sub standard assembly.

A transducer is connected via a co-axial cable to the hand held instrument with readings captured as close to the centre line and perpendicular to the component of interest.

If you then had to go and download, use complicated software, and have years of experience to interpret readings this would become a long winded process for very little gain so would probably have little or no benefit.

I'm all about providing a benefit before using any technology, this AE device simplifies this by crunching data in the collector, transposing it to an easy to understand figure that can be compared to the previous reading for immediate action.

It is then saved to the database providing a trend over time.

Multiple data points and routes can be inspected, downloaded into a history file that trends points and flag warnings if required.

It can also capture Spectra readings that are transposed with FFT (Fast Fourier Transform) to analyse specific frequencies associated with outer/inner race, cage, element, journal or ball spin frequency.

This analysis pinpoints early damage like spalling or fretting inside bearing assemblies (see photo above).

So how does it work?

Imagine a defect on a single roller in a bearing, every time that imperfection contacts the inner or outer race it sends out a high frequency low amplitude 'ping'; some refer to this as Shock Pulse or Spike Energy, hopefully you get the idea.

If we record and track this anomaly over time, trend its journey then we will witness the degradation from a very early state before things get bad enough for vibration to be detected readily.

We have an advanced warning to plan bearing, asset replacements or overhauls in a planned event; maybe in a product change or planned maintenance window.

It can also be used as a pure Condition Based Maintenance tool to target a Lubrication program.

I've removed many fixed time Lubrication tasks that risked under or over lubrication, acting upon the AE outputs only.

This reduces expensive planned labour time, lubricant use, enhances lifespan of assets and equipment efficiency.

I have just covered the basics of AE, hopefully it has given you an insight.

I have a short course about AE available on UPTIME Consultant Academy® if you want to find out more.

If you then had to go and download, use complicated software, and have years of experience to interpret readings this would become a long winded process for very little gain so would probably have little or no benefit.

I'm all about providing a benefit before using any technology, this AE device simplifies this by crunching data in the collector, transposing it to an easy to understand figure that can be compared to the previous reading for immediate action.

It is then saved to the database providing a trend over time.

Multiple data points and routes can be inspected, downloaded into a history file that trends points and flag warnings if required.

It can also capture Spectra readings that are transposed with FFT (Fast Fourier Transform) to analyse specific frequencies associated with outer/inner race, cage, element, journal or ball spin frequency.

This analysis pinpoints early damage like spalling or fretting inside bearing assemblies (see photo above).

So how does it work?

Imagine a defect on a single roller in a bearing, every time that imperfection contacts the inner or outer race it sends out a high frequency low amplitude 'ping'; some refer to this as Shock Pulse or Spike Energy, hopefully you get the idea.

If we record and track this anomaly over time, trend its journey then we will witness the degradation from a very early state before things get bad enough for vibration to be detected readily.

We have an advanced warning to plan bearing, asset replacements or overhauls in a planned event; maybe in a product change or planned maintenance window.

It can also be used as a pure Condition Based Maintenance tool to target a Lubrication program.

I've removed many fixed time Lubrication tasks that risked under or over lubrication, acting upon the AE outputs only.

This reduces expensive planned labour time, lubricant use, enhances lifespan of assets and equipment efficiency.

I have just covered the basics of AE, hopefully it has given you an insight.

I have a short course about AE available on UPTIME Consultant Academy® if you want to find out more.

But if it's so good and user friendly, why is it not as popular as Vibration?

Firstly it is niche, not many manufacturers exist that produce analysers or associated software.

Vibration has hundreds of options for equipment, many standards that support the technology.

Some practitioners are protective, like to guard Predictive as a 'black art' that needs years of qualification and experience.

In some spheres that can be true; you may need a degree in Vibration to understand some data outputs.

For me Vibration and AE co-exist as tools in the Condition Monitoring toolkit, along with Ultrasound and Thermography, each has strengths or weakness depending on the asset mode of failure.

Strengths wise AE is largely unaffected by background noise, it is more sensitive to faults under normal running, applicable to all machines at almost all running speeds, presents faults at the asset and provides good parameters to trend from.

On the other hand it needs specialist transducers and signal processing, it's sensitive to turbulence and crushing forces, so it doesn't like turbines, chains, or some servos that emit ultrasonics.

These can sometimes be mitigated if you know what you are doing.

It's not sensitive to minor imbalance, mis-alignment or bent shafts; aspects Vibration is very good at measuring.

Vibration has hundreds of options for equipment, many standards that support the technology.

Some practitioners are protective, like to guard Predictive as a 'black art' that needs years of qualification and experience.

In some spheres that can be true; you may need a degree in Vibration to understand some data outputs.

For me Vibration and AE co-exist as tools in the Condition Monitoring toolkit, along with Ultrasound and Thermography, each has strengths or weakness depending on the asset mode of failure.

Strengths wise AE is largely unaffected by background noise, it is more sensitive to faults under normal running, applicable to all machines at almost all running speeds, presents faults at the asset and provides good parameters to trend from.

On the other hand it needs specialist transducers and signal processing, it's sensitive to turbulence and crushing forces, so it doesn't like turbines, chains, or some servos that emit ultrasonics.

These can sometimes be mitigated if you know what you are doing.

It's not sensitive to minor imbalance, mis-alignment or bent shafts; aspects Vibration is very good at measuring.

How does Acoustic Emission work?

The Condition Monitoring technology of Acoustic Emission is one where I have decades of experience applying it to assets in the Food, Automotive and Utility sectors, with multiple examples of cost benefits and case studies

The technology is transferrable to any industry that uses rotational equipment, it can also be used as a device to monitor pneumatic systems in a similar way to Ultrasound.

The Holroyd MHC Memo Pro, is a simple to use instrument in the field.

I've trained reliability engineers, technicians, maintenance engineers, and operators how to use this data-logger including, equipment criticality, taking meaningful readings, how to approach inspection routes, database trending, signature triggers and Spectrum Analysis.

Holroyd Kittiwake have produced a few YouTube videos if you would like to take a closer look, the best one by far is in the one below as it gives a really good understanding of this technology and the instrument

If you would like more information please give me a call or email me at [email protected]

I own multiple Holroyd MHC Memo Pros as demonstrated in this video.

If you are interested in finding out more about the technology, have critical assets you need inspecting please get in touch.

The technology is transferrable to any industry that uses rotational equipment, it can also be used as a device to monitor pneumatic systems in a similar way to Ultrasound.

The Holroyd MHC Memo Pro, is a simple to use instrument in the field.

I've trained reliability engineers, technicians, maintenance engineers, and operators how to use this data-logger including, equipment criticality, taking meaningful readings, how to approach inspection routes, database trending, signature triggers and Spectrum Analysis.

Holroyd Kittiwake have produced a few YouTube videos if you would like to take a closer look, the best one by far is in the one below as it gives a really good understanding of this technology and the instrument

If you would like more information please give me a call or email me at [email protected]

I own multiple Holroyd MHC Memo Pros as demonstrated in this video.

If you are interested in finding out more about the technology, have critical assets you need inspecting please get in touch.